Testing Compressor Safety Devices (IIAR 6, Part 11)

Is it acceptable to test a high discharge pressure cutout (HPCO) by lowering the setpoint?

Maybe.

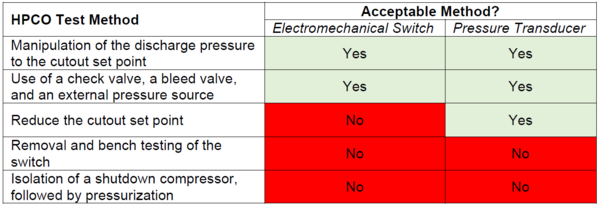

ANSI/IIAR 6-2019 §6.1.1 prescribes the allowable methods for testing a compressor HPCO which is required annually per Table 6.1. Depending on the type of pressure limiting device being used, allowable methods differ.

Electromechanical Switch

Electromechanical switches are widely used on reciprocating compressors. To functionally test an electromechanical switch, §6.1.1.1.1 requires one of the following methods:

- Manipulation of the discharge pressure to the cutout set point

- Use of a check valve, a bleed valve, and an external pressure source

- 6.1.1.1.2 prohibits the use of the following methods:

- Removal and bench testing of the switch.

- Isolation of a shutdown compressor, followed by pressurization.

- Reduce the cutout set point.

Pressure Transducer or Transmitter

Pressure transducers are often utilized on screw compressors. When pressure transducers are used, §6.1.1.2.1 requires one of the following test methods:

- Manipulation of discharge pressure to the cutout set point.

- Reduce the cutout set point and raise the discharge pressure until shutdown occurs.

- Using a check valve, a bleed valve, and an external pressure source.

6.1.1.2.2 prohibits the testing from being performed using:

- Removal and bench testing of the pressure transducer or transmitter.

- Isolation of a shutdown compressor, followed by pressurization.

To summarize, IIAR 6 lists five methods for testing HPCOs. Two methods are approved, two methods are prohibited, and one method can be used selectively (pressure transducers only). The table below summarizes methods listed in IIAR 6:

Appendix A includes helpful commentary regarding each method. For example, in §A.6.1.1.1 there is explanation for manipulating the discharge pressure:

“The compressor discharge pressure should be increased slowly either by raising the condensing pressure or throttling the compressor discharge stop valve (slowly closing and NEVER shutting the valve)“

Additionally, when testing a pressure transducer HPCO by reducing the cutout set point, §A.6.1.1.2 explains that the transducer “should be verified at two pressures that are 10% or more apart to verify the accuracy of the calibration programmed into the controls“.

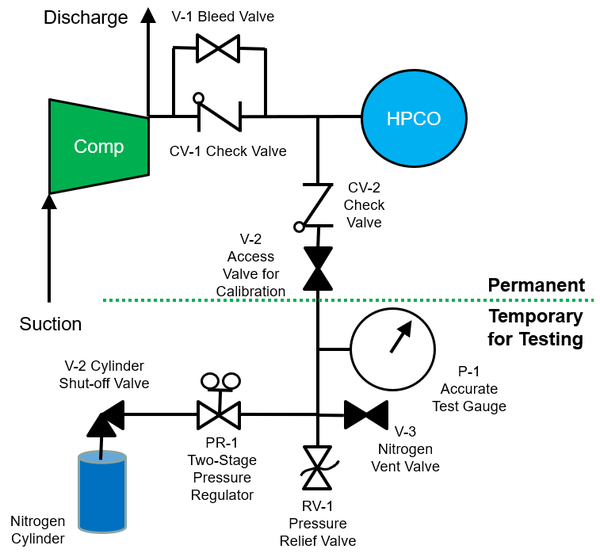

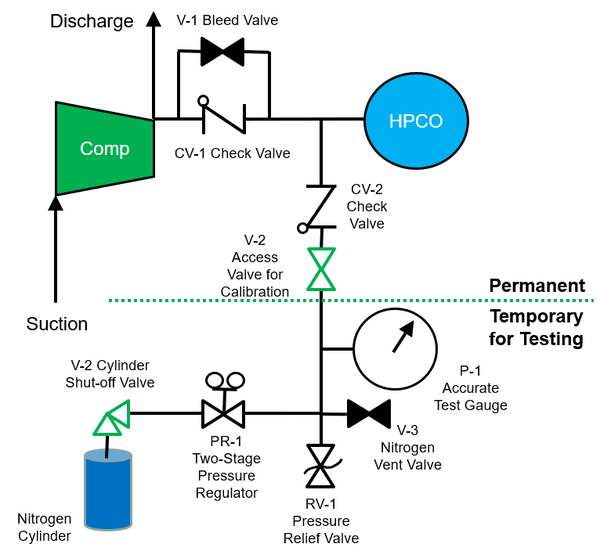

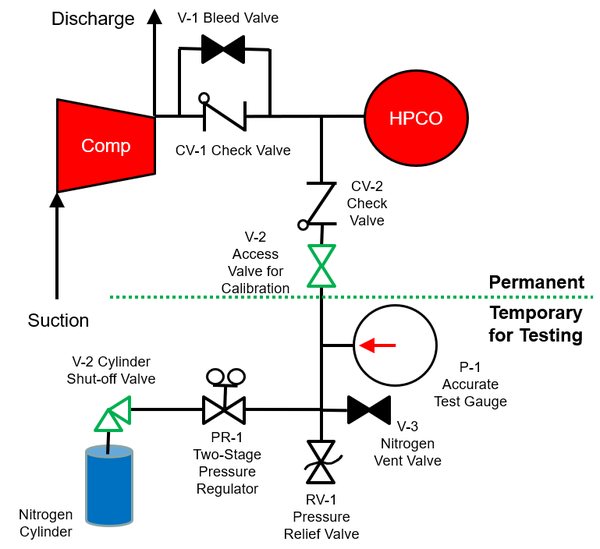

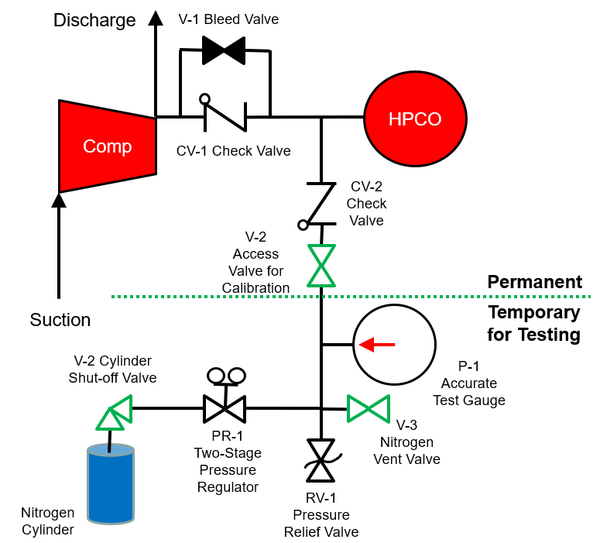

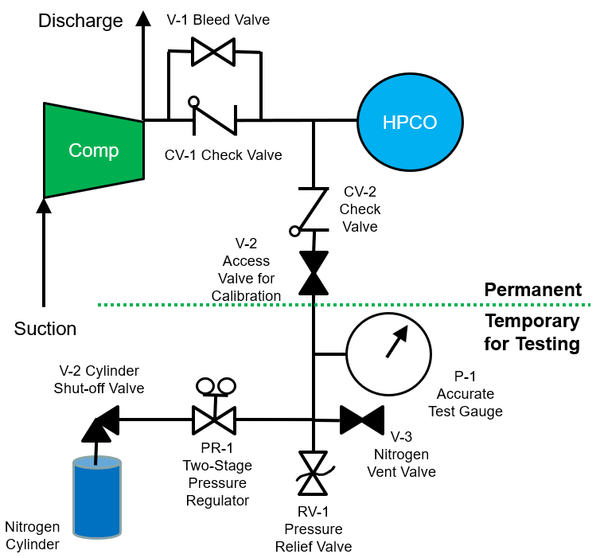

Since testing of a HPCO through the “use of a check valve, a bleed valve, and an external pressure source” is acceptable regardless of the type of device, Appendix A Figures 1-2 depict how such an arrangement might look:

Using this configuration, the testing could be performed by closing Bleed Valve (V-1) and opening Access Valve for Calibration (V-2). Then the pressure can be raised by opening the Cylinder Shut-off Valve (V-2).

Assuming the test is successful, the compressor will shut down once the HPCO setpoint is reached.

Before placing the unit back into normal operation, the nitrogen can be purged from the unit by opening the Nitrogen Vent Valve (V-3).

Once the nitrogen has been purged, the unit can be placed back into service after Bleed Valve (V-1) has been opened and Access Valve for Calibration (V-2) has been closed.

This is Part 11 of a series on IIAR 6. You can access previous blogs in this series below:

Leave a Reply