What-If/Checklist Methodology (Part 7)

There are several PHA methodologies listed in the RMP, PSM, and CalARP regulations. The International Institute of Ammonia Refrigeration (IIAR) recommends using the What-If/Checklist methodology for ammonia refrigeration PHAs.

The What-If/Checklist methodology is easy to understand since each question begins with the words “What if…”

The simplest way to explain how this methodology is implemented is to walk through an example.

Most ammonia refrigeration systems are configured with a high pressure receiver. A common “what if” question to ask regarding a high pressure receiver is “What if the vessel or associated components are damaged by nearby activity?”

At Resource Compliance, for each “What if” question that is posed, we discuss at least one scenario with a negative outcome associated with the question. For example, in this question, the scenario might be that “an employee accidentally swings a ladder which impacts and breaks the high pressure receiver sight glass”.

If this were to occur, the consequences could be dire. Since the vessel contains high pressure liquid ammonia, a release from this vessel could result in any combination of the consequences listed below.

- Death

- High pressure liquid ammonia release

- Injury

- Reactive maintenance

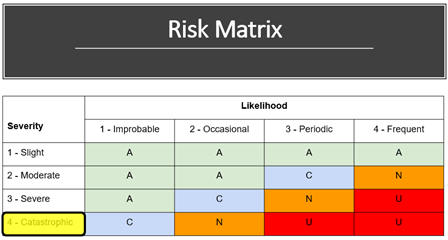

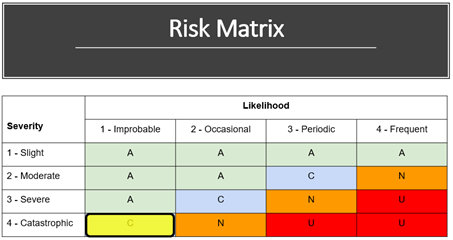

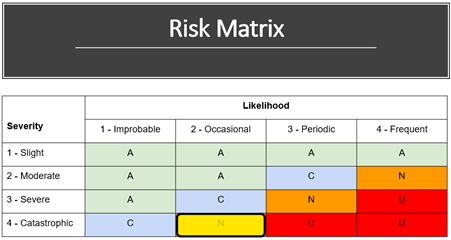

With that in mind, ‘severity’ is rightly classified as ‘4’ or ‘catastrophic’.

Now consider the likelihood of this occurrence. We will explore two different installations and the effect on likelihood.

First, consider this vessel configuration. In this example, the high pressure receiver has a bull’s eye column which is constructed of steel pipe and robust, crack resistant sight glasses.

Based on the configuration of the vessel and conversation with team members, we may conclude that the safeguards displayed below have been implemented at the facility.

- Each of the valves on the high pressure receiver is adequately protected from inadvertent impact.

- Facility personnel (including forklift drivers) have been trained to take extra care when working around the refrigeration equipment and other utilities equipment (e.g. electrical transformers).

- The high pressure receiver is located inside the machinery room which is restricted to authorized personnel only.

- The sight glass on the high pressure receiver is a bull’s eye column type which can withstand most minor physical impact.

Because of the robust safeguards, it is improbable that the scenario will occur and therefore a risk ranking of ‘C’ was assigned. ‘C’ designates “controlled risk” in our matrix.

If on the other hand, the vessel is configured with a solid glass tube, it would be much more susceptible to breakage due to a swinging ladder or other impact.

Therefore, two of the four safeguards we previously listed would no longer be applicable.

- Each of the valves on the high pressure receiver is adequately protected from inadvertent impact.

- Facility personnel (including forklift drivers) have been trained to take extra care when working around the refrigeration equipment and other utilities equipment (e.g. electrical transformers).

- The high pressure receiver is located inside the machinery room which is restricted to authorized personnel only.

- The sight glass on the high pressure receiver is a bull’s eye column type which can withstand most minor physical impact.

Due to the lack of safeguards, the PHA team may regard the likelihood of occurrence ‘occasional’. The combination of a severity of ‘4’ and a likelihood of ‘2’ results in a risk ranking of ‘N’ or “not desirable”. Where unacceptably high risk rankings are assigned, recommendations should be made to reduce the danger associated with the event occurring.

The steps that were just explained to arrive at a risk ranking will be repeated for each question in the What-If/Checklist. In order to focus attention, PHAs typically divide systems into subsystems or nodes. Once all questions for a single subsystem have been considered, the team will move on to the next subsystem. This is repeated until all subsystems have been studied.

This is Part 7 of a series on PHAs. You can access previous blogs in this series below:

Leave a Reply