Management of Change & Pre-Startup Safety Review (Part 3)

In Part 1 of this series, we examined the purpose of Management of Change and Pre-Startup Safety Review (MOC/PSSR) and how to determine when it is required. In Part 2 of the series, we reviewed the specific requirements of MOC/PSSR. While it may feel like a daunting task, we will now review how to implement Management of Change and Pre-Startup Safety Review (MOC/PSSR) procedures. Taking shortcuts may be easy at the time, but can lead to an accident during startup or headaches at the next inspection or PHA. The following strategies will clarify how to get the right procedures and people in place when a change is needed.

Initiate Early

A proper MOC/PSSR should be considered early and long before an operator or contractor is making equipment changes. Ideally, a project scope would be reviewed against the MOC/PSSR procedures. This is often facilitated through written checklists. By initiating early, design requirements, PHAs, building permits and system shutdown can all be planned. This is far better than a reactionary approach that is seen all too often.

Use Applicable Procedures and Checklists

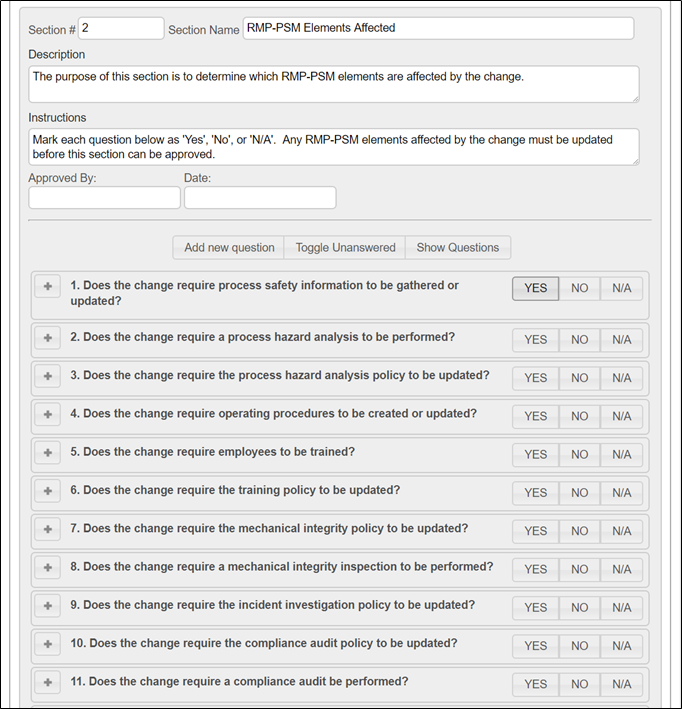

MOC/PSSRs are usually facilitated through checklists which ask a series of questions for compliance conformity. Ensure that your checklists meet the minimum requirements set forth in Part 2 and other PSM regulations that apply to your process.

Portion of an electronic MOC checklist

MOC/PSSR checklists should consider industry specific codes and standards. Requesting written Design Codes and Standards Employed from contractors during the proposal phase is important when comparing quotes. The lowest bidder might cost you a lot more in the end if what they install is built to an outdated code or standard. Additionally, this provides excellent documentation to add to your PSI. For ammonia refrigeration processes, ANSI/IIAR 2-2014 provides current design standards. ANSI/IIAR 5-2013 Start-up and Commissioning of Ammonia Refrigeration Systems can also be incorporated into the PSSR checklist. This is a valuable document for you and your contractor to follow.

Get the Right People Involved

MOC/PSSR checklists are only as good as the people filling them out. The review should include all affected parties with varied fields of expertise. This is particularly important for complex changes and is always helpful when analyzing the impact on health and safety. Employees should be selected based upon their experience and understanding of the process being evaluated. For example, the construction of a new process may include coordination between:

- Facility Management

- Safety Coordinator or Safety Team

- Process Operators

- Installing Contractor

- Design Engineer

- PSM Consultant

- CUPA Representative (California only; see our blog on Process Modifications)

On the other hand, a small piping change may only be reviewed by the design engineer, operators and safety team. Remember: determining the impact on safety and health is the chief concern, so be thorough in talking through questions and potential scenarios. Whenever the risk is too high, engineering or administrative controls should be put in place prior to startup. For example, an administrative policy could prevent forklift drivers from stacking bins close to the new process equipment.

Keep Organized Documentation

As with most programs, “If it wasn’t documented, it didn’t happen.” Stay organized by keeping all MOC/PSSR documentation in one place. Your checklists should have notes summarizing the documents which need to be updated, who is responsible, when they were collected and a final sign-off. You can imagine a major change affecting all PSM elements from PSI to the Emergency Response Plan. The best practice is to have a system and keep it organized.

By implementing these MOC/PSSR strategies, your program will be updated accordingly. More importantly, you can rest assured knowing that you are maintaining a process that is safe for your employees and the surrounding community.

DOES A VALVE CHANGE OF LIKE KIND REQUIRE AN M.O.C. ESC. VALVE BONNET REPLACEMENT ONLY

No. So long as the change is “like for like”, MOC is not required.