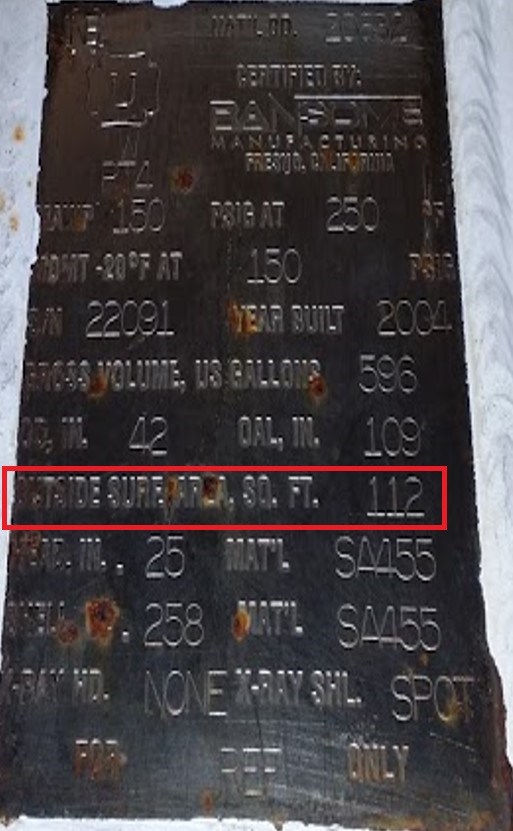

Ammonia Pressure Vessel Nameplates

Pressure vessels are used pervasively in the ammonia refrigeration industry for a variety of different functions. It is required that every vessel be constructed in accordance with ASME B&PV Code Section VIII, Division 1. The quickest way to verify that the design and construction requirements have been met is by inspecting the vessel nameplate. The following is a summary of the required components of a pressure vessel installed for ammonia refrigeration service.

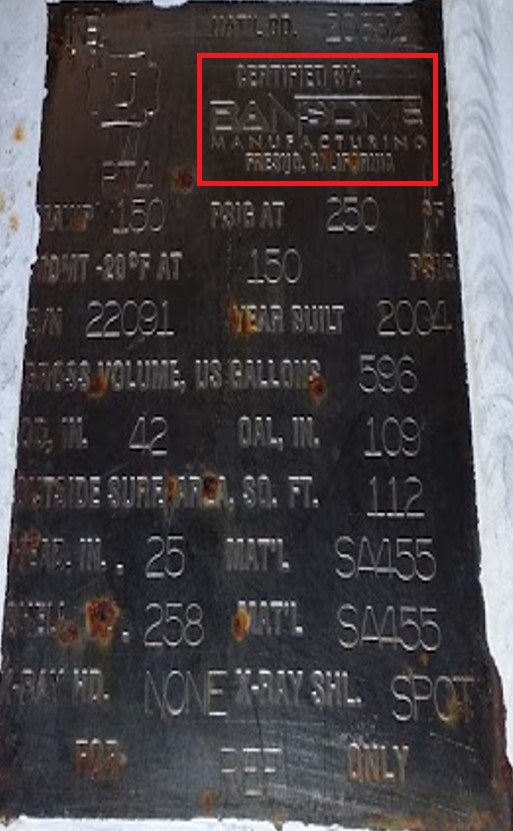

Manufacturer’s Name

Code Basis: ANSI/IIAR 2-2014 §12.4.1(1), IIAR Bulletin No. 109 §4.1.2(a), 2015 ASME B&PV Code Section VIII UG-116(a)(2), 2015 ASME B&PV Code Section VIII UG-119(a)

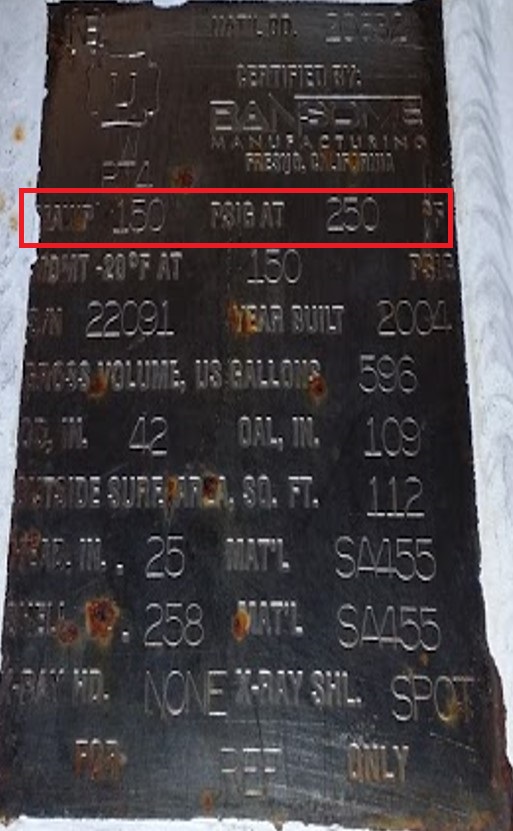

Maximum Allowable Working Pressure

Code Basis: ANSI/IIAR 2-2014 §12.4.1(2), IIAR Bulletin No. 109 §4.1.2(e), 2015 ASME B&PV Code Section VIII UG-116(a)(3), 2015 ASME B&PV Code Section VIII UG-119(a)

Comment: The maximum allowable working pressure must be displayed as:

“Maximum allowable working pressure (MAWP) _____ at _____ temperature.”

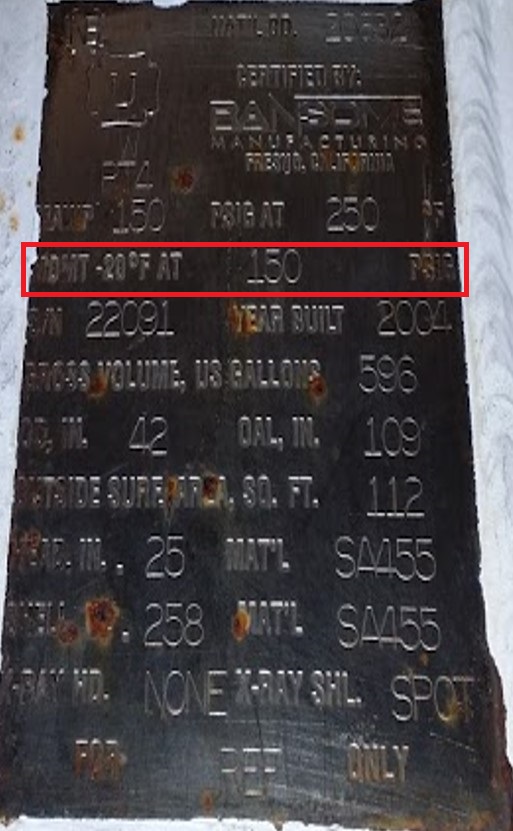

Minimum Design Metal Temperature

Code Basis: ANSI/IIAR 2-2014 §12.4.1(3), 2015 ASME B&PV Code Section VIII UG-116(a)(4), 2015 ASME B&PV Code Section VIII UG-119(a)

Comment: The minimum design metal temperature must be displayed as:

“Minimum design metal temperature (MDMT) _____ at _____ pressure.”

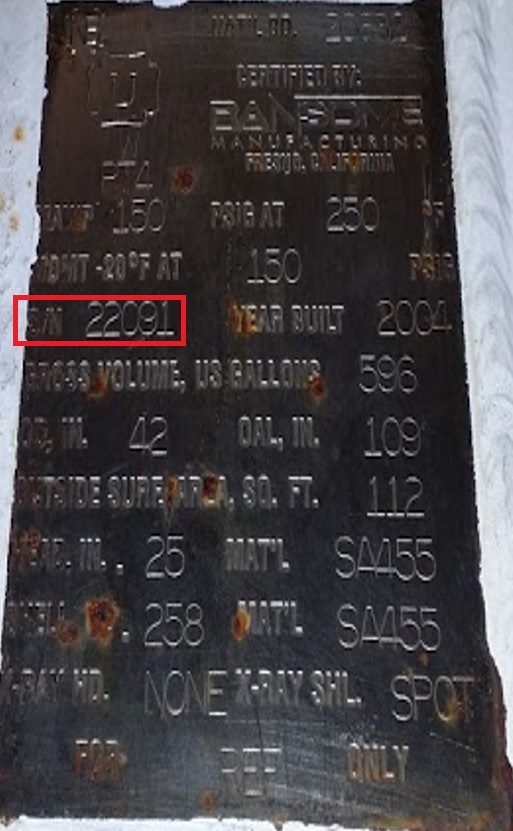

Serial Number

Code Basis: ANSI/IIAR 2-2014 §12.4.1(4), IIAR Bulletin No. 109 §4.1.2(b), 2015 ASME B&PV Code Section VIII UG-116(a)(5), 2015 ASME B&PV Code Section VIII UG-119(a)

Comment: Additionally, the “Model Number” must be included if the vessel manufacturer utilizes such a number.

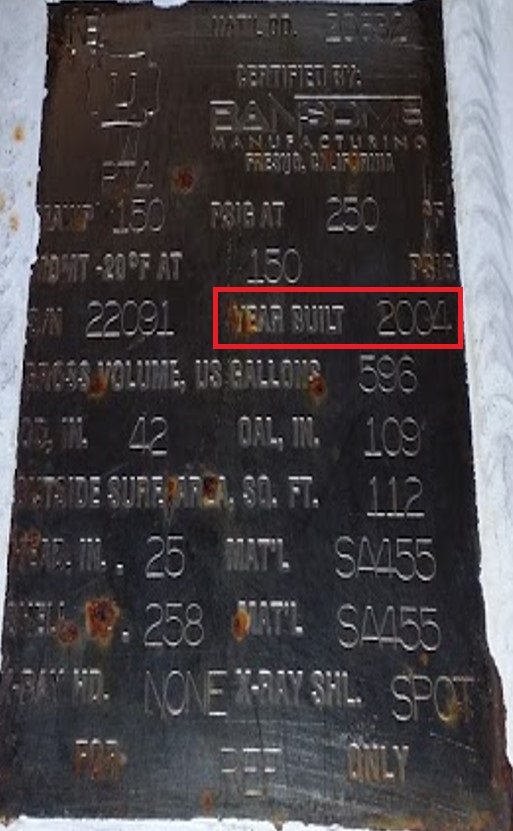

Year of Manufacture

Code Basis: ANSI/IIAR 2-2014 §12.4.1(5), IIAR Bulletin No. 109 §4.1.2(d), 2015 ASME B&PV Code Section VIII UG-116(a)(6), 2015 ASME B&PV Code Section VIII UG-119(a)

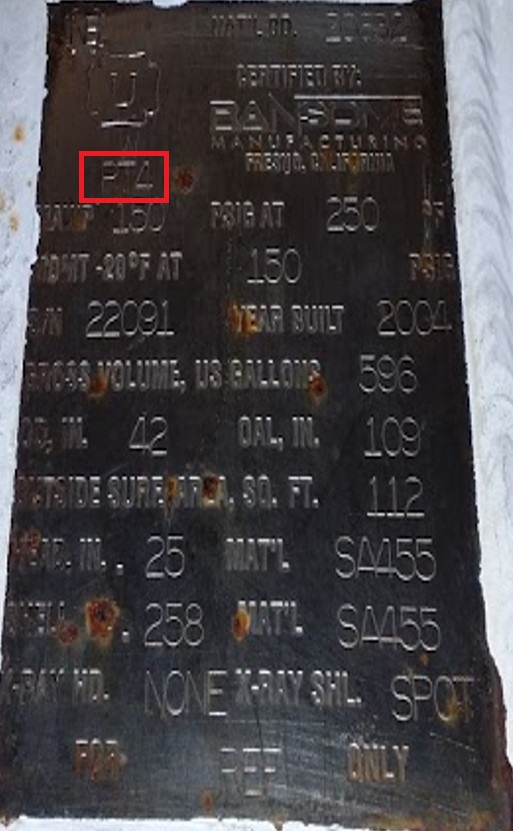

Official Certification Mark (ASME Stamp)

Code Basis: ANSI/IIAR 2-2014 §12.4.1(7), IIAR Bulletin No. 109 §4.1.2, 2015 ASME B&PV Code Section VIII UG-116, 2015 ASME B&PV Code Section VIII UG-119(a)

Radiography Code

Code Basis: 2015 ASME B&PV Code Section VIII UG-116(e), 2015 ASME B&PV Code Section VIII UG-119(a)

Comment: When radiographic or ultrasonic examination has been performed on a vessel, an “RT” stamp must be included on the nameplate:

- RT 1 – when all pressure-retaining butt welds, other than Category B and C butt welds associated with nozzles and communicating chambers that neither exceed NPS 10 (DN 250) nor 1% in. (29 mm) wall thickness [except as required by UHT-57(a)], satisfy the full radiography requirements of UW-11(a) for their full length; full radiography of the above exempted Category Band C butt welds, if performed, may be recorded on the Manufacturer’s Data Report; or

- RT 2 – when the complete vessel satisfies the requirements of UW-11(a)(5) and when the spot radiography requirements of UW-11(a)(5)(-b) have been applied; or

- RT 3 – when the complete vessel satisfies the spot radiography requirements of UW-11(b); or

- RT 4 – when only part of the complete vessel has satisfied the radiographic requirements of UW-11(a) or where none of the markings “RT 1,” “RT 2,” or “RT 3” are applicable. The extent of radiography and the applicable joint efficiencies shall be noted on the Manufacturer’s Data Report.

National Board Number

Code Basis: IIAR Bulletin No. 109 §4.1.2(g)

Comment: The vessel must be equipped with a National Board number if it is registered with the organization. National Board registration is not a requirement of ANSI/IIAR 2-2014 or ASME B&PVC Section VIII, Division 1.

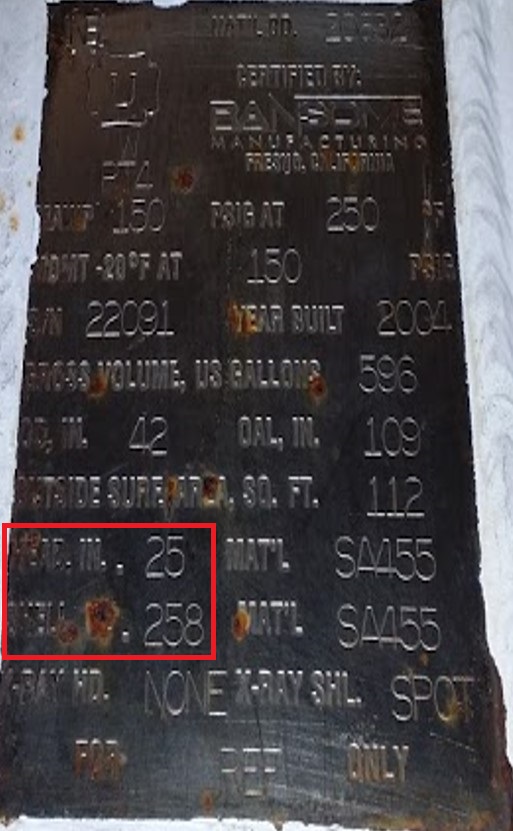

Head and Shell Thickness

Code Basis: Title 8 CCR §458(a)(1)

Comment: This is a requirement of Cal/OSHA and applies to vessels installed in California only.

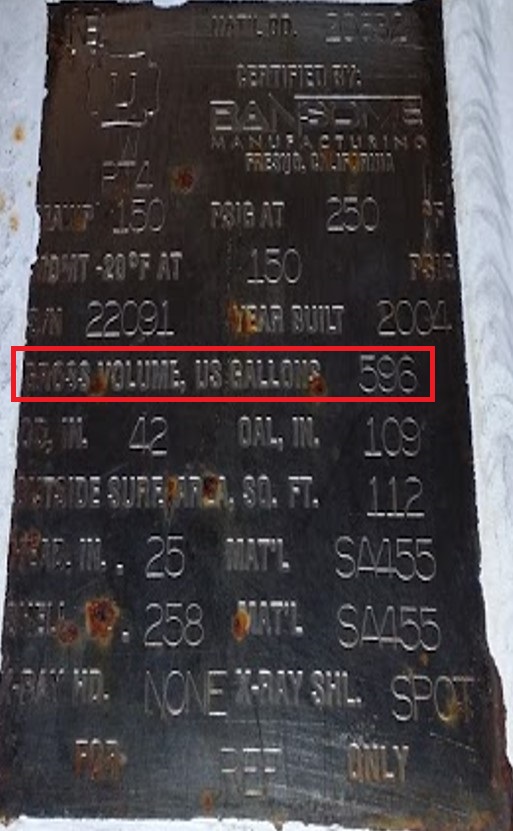

Volume

Code Basis: Title 8 CCR §458(a)(2)

Comment: This is a requirement of Cal/OSHA and applies to vessels installed in California only.

Surface Area

Code Basis: Title 8 CCR §458(a)(3)

Comment: This is a requirement of Cal/OSHA and applies to vessels installed in California only.

For more about nameplates, see our previous blog posts:

Leave a Reply