ASME Pressure Vessel Modification

A client recently modified an ASME ammonia pressure vessel that provided me the opportunity to dive into the requirements that must be adhered when performing such activities. Here is a summary of what I learned:

1. IIAR Standards

IIAR doesn’t speak directly to the issue of pressure vessel modification, however, ANSI/IIAR 2-2008 Addendum B §9.2 Procedures/Testing does address the topic of pressure vessel construction in general:

Pressure vessels shall be tested per the provisions of the governing edition of Section VIII, Division 1, ASME Boiler and Pressure Vessel Code [ref.4.1.1], if applicable. Otherwise, they shall be tested and proven tight by the manufacturer at a pressure not less than the maximum allowable working pressure for which they are rated.

As is evident in the section above, IIAR 2 requires all vessels to be constructed in accordance with ASME B&PV Code.

2. National Board Inspection Code

The National Board Inspection Code, is divided into three (3) Parts:

- Part 1 – Installation

- Part 2 – Inspection

- Part 3 – Repairs and Alterations

There are several noteworthy requirements in Part 3 of NBIC:

General Requirements (2013 NBIC §1.2(a))

When the standard governing the original construction is the ASME Code or ASME RTP-1, repairs and alterations to pressure-retaining items shall conform, insofar as possible, to the section and edition of the ASME Code most applicable to the work planned.

Inspector/Authorization/

Per 2013 NBIC §1.3, all repairs and alterations must be inspected and authorized by an Authorized Inspection Agency. The company performing the modification is required to receive National Board Accreditation (procedure for accreditation is outlined in 2013 NBIC §1.5) in order to use the “R” stamp. Part of the accreditation process is the development of a Quality System (2013 NBIC §1.6) which the company must have available for review upon request. The Quality System Manual should indicate which construction code requirements are being followed for the repair/alteration.

2.3. Material Requirements for Repairs and Alterations (2013 NBIC §3.2.1)

a) The materials used in making repairs or alterations shall conform insofar as possible to the original code of construction or construction standard or code selected, including the material specification requirements used for the work planned…

c) When ASME is the original code of construction, replacement parts subject to internal or external pressure fabricated by welding, which require inspection by an Authorized Inspector shall be fabricated by an organization having an appropriate ASME Certificate of Authorization. The item shall be inspected and stamped as required by the applicable section of the ASME Code. A completed ASME Manufacturer’s Partial Data Report shall be supplied by the manufacturer;

To summarize the excerpts above, it is expected that the repair/alteration would conform to the ASME B&PV Code and that the company performing the vessel modification would provide a partial/revised data report upon completion. An example of a Data Report with revisions revisions, can be seen here.

2.4. Drawings (2013 NBIC §3.2.3)

As appropriate, drawings shall be prepared to describe the repair or alteration. Drawings shall include sufficient information to satisfactorily perform the repair or alteration.

2.5. Design Requirements for Repairs and Alterations (2013 NBIC §3.2.4(b))

The “R” Certificate Holder performing repairs and alterations shall establish the construction standard or code and sufficient controls to ensure that all required design information, applicable drawings, design calculations, specifications, and instructions are prepared, obtained, controlled, and interpreted to provide the basis for a repair or an alteration in accordance with the original code of construction. When a Manufacturer’s Data Report is required by the original construction standard, a copy of the original data report shall be obtained, where available, for use in the design of the repair or alteration. When the original Manufacturer’s Data Report cannot be obtained, agreements on the method of establishing design basis for the repair or alteration shall be obtained from the Inspector and the Jurisdiction, when required.

2.6. Calculations (2013 NBIC §3.2.5)

For alterations, calculations shall be completed prior to the start of any physical work. All design calculations shall be completed by an organization experienced in the design portion of the standard used for construction of the item. All calculations shall be made available for review by the Inspector accepting the design.

2.7. Repair vs. Alteration

The NBIC lists several examples of both repairs (§3.3) and alterations (§3.4). Examples of repairs are:

- replacement/repair of welds that have failed

- addition of welded attachments

- replacement of tube sheets or tubes in a heat exchanger

- installation of new nozzles that do not effect the original vessel strength calculations

Examples of alterations are:

- re-rating a vessel for a higher temperature or pressure

- re-rating a vessel based on new code edition and new material strength and wall thickness requirements

- addition of new nozzles and openings that are not classified as a repair (see above)

- change in dimensions of a vessel

With this in mind, it is important to determine whether the vessel is being repaired or altered as the requirements differ for each category. In either case, requirements for the repair/alteration a spelled out in NBIC.

2.8. Examination and Testing

2013 NBIC §4 outlines the requirements for Examination and Testing after performing a repair or alteration. It is beyond the scope of this blog to go into great detail about the various methods of examination, but important to note the following:

For a repair, exclusive use of Visual Examination is permitted if other methods are not practicable and the repair is classified as “routine” (definition of routine is in §3.3.2). The person performing the visual inspection must be qualified and certified in accordance with AWS QC-1. The visual examination must be accompanied by a written procedure and a report of the examination results. Exclusive use of Visual Examination is not allowed for alterations.

2.9. Certification/Documentation and Stamping

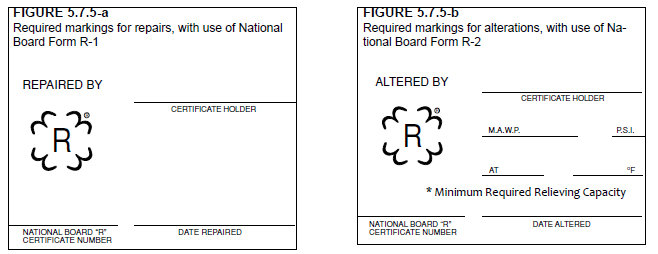

Per 2013 NBIC §5.2 either an R-1 (repair) or R-2 (alteration) form must be prepared and available at the facility and submitted to the National Board.

2013 NBIC §5.7.5 outlines the various requirements for nameplates/stamping. It is worth noting that the nameplate/stamp requirements differ for an alteration as compared to a repair as is depicted in the images below.

3. Summary

I trust this blog will give you some helpful resources to get a jump start on the process of modifying a pressure vessel. Consult ASME Boiler and Pressure Vessel Code and the National Board Inspection Code in their entirety to learn more about the design and alteration of pressure vessels.

is it possible to convert the coalescer vessel to three phase separator by doing internally modification.

and are the requirement to do that

Unfortunately, this is not application that we have personal experience with. However, if the internal components of the vessel are part of the ASME-certification, then modifying that would require an R-stamp.