Ammonia Release | Compressor Suction Gasket

Summary

In June 2020, the failure of a bolt on the strainer cap for a compressor led to the release of 5,461 lbs of ammonia. One of the four bolts for the strainer cap had been broken for years. A second bolt broke during the incident as the compressor suction gasket failed.

Incident Description

When the compressor HSS gasket failed, low pressure ammonia vapor was released into the machinery room. The ammonia detectors in the room began to alarm and the ventilation fans were automatically activated. An operator remotely shut down the compressors inside the machinery room and left the condensers running.

Notifications of the leak were made and the fire department, a refrigeration contractor, and a Hazmat team arrived on site. The ammonia detector concentration display was visible from outside the machinery room by using binoculars. The detector displayed an ammonia concentration of 800 ppm, which was the highest concentration it was capable of displaying. The Hazmat team donned Level A Hazmat suits and entered the machinery room where they recorded a peak ammonia concentration of 8,300 ppm. At the time, the source of the ammonia leak was unknown. Therefore, the king valve was closed along with several valves associated with the auto-purger. Eventually, the source of the leak was discovered at a compressor high stage suction strainer. The compressor suction and discharge valves were isolated and the leak dissipated.

Release Calculation

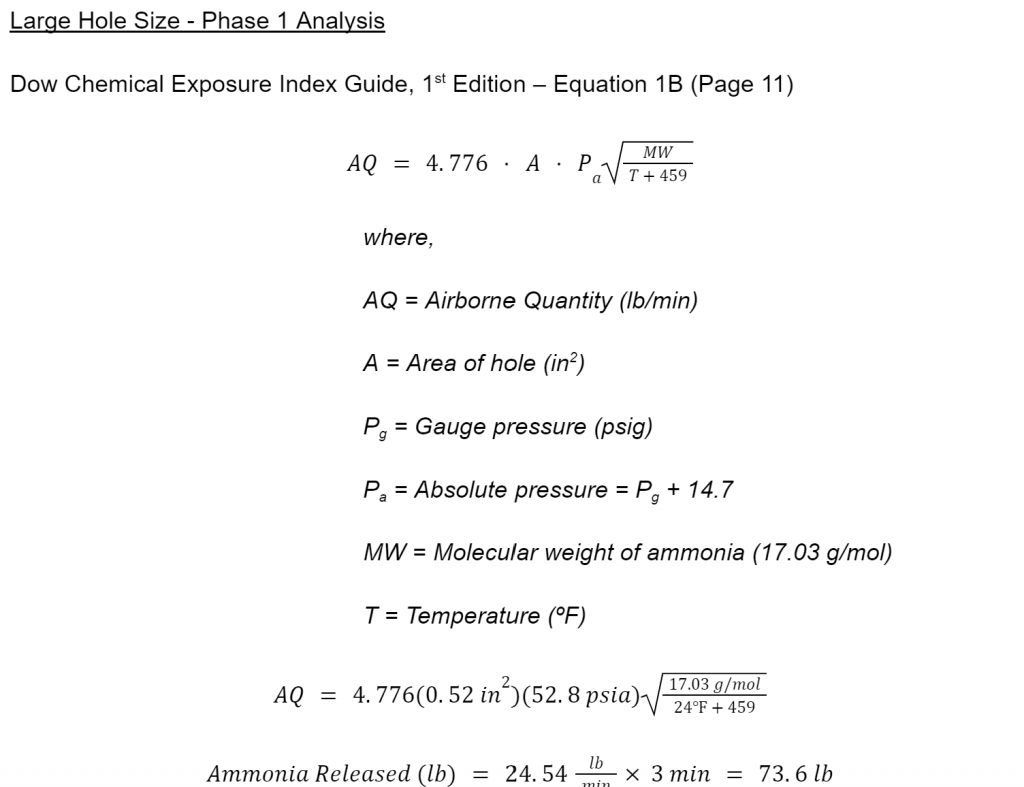

The release calculation was complex due to the unusual hole shape and size. The ammonia release calculation states the following:

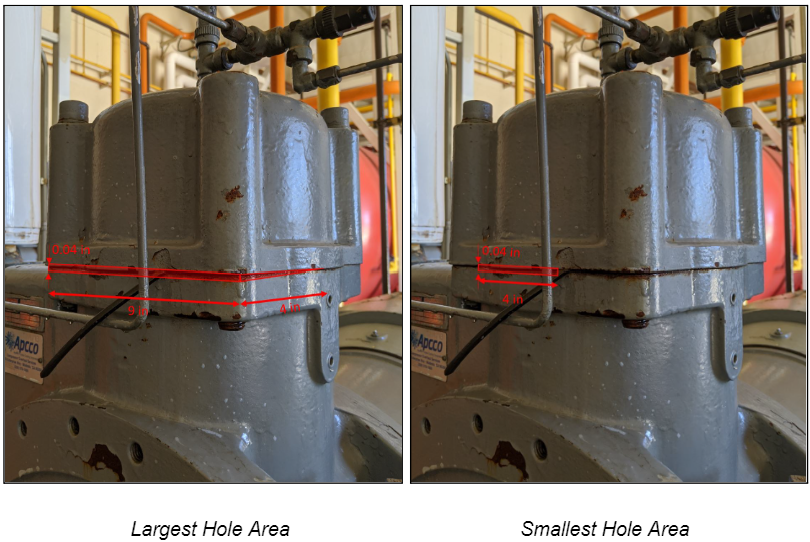

“A gasket inside the strainer tore and approximately 4 inches of the gasket was forced out of the strainer at the time of the release. Due to the nature of the hole, two area calculations were performed: one area calculation assuming the largest possible hole area, and another assuming the smallest possible hole area.”

Largest Hole Area Smallest Hole Area

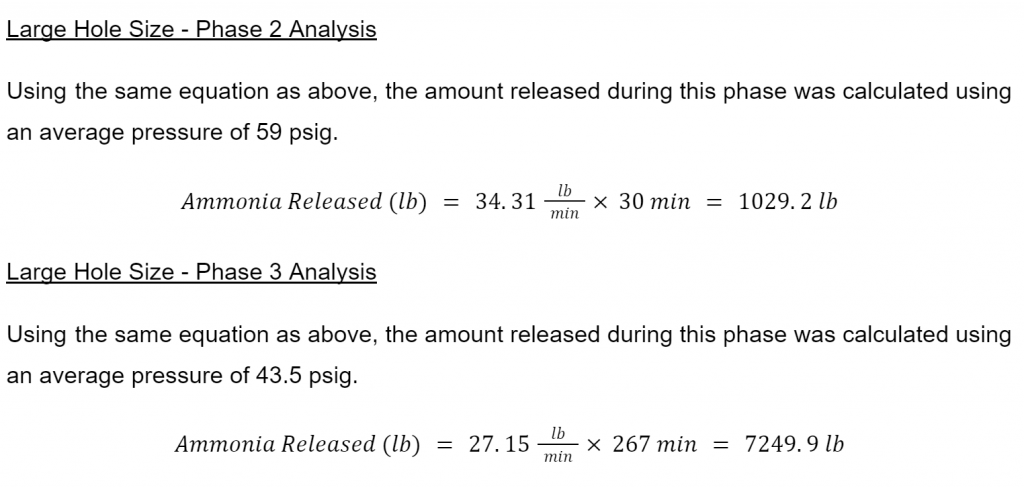

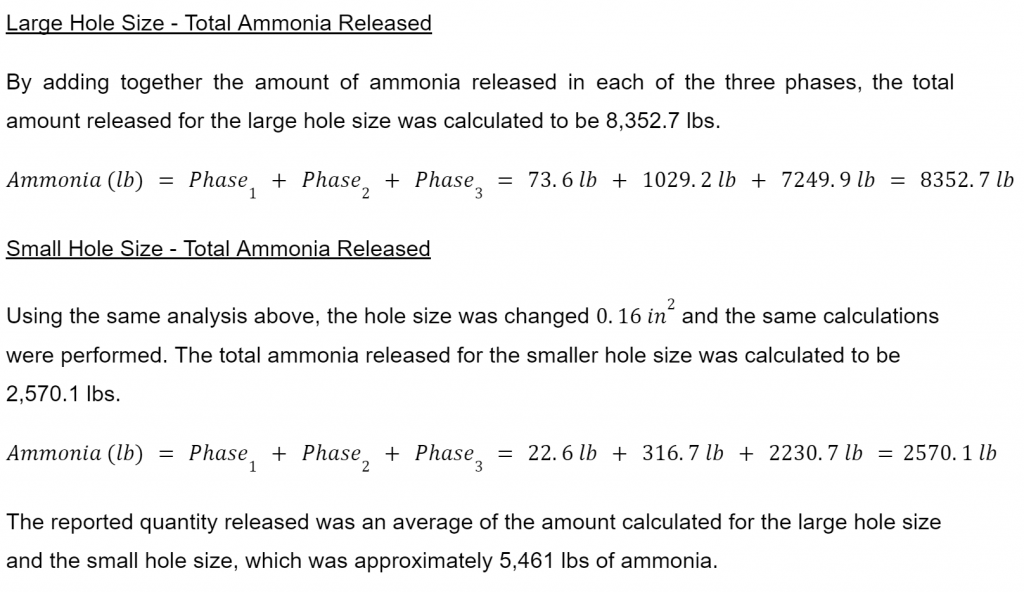

A release calculation was also performed for three separate phases of the release. Each of the phases represents a different change in pressure of the ammonia vapor.

- Phase 1 – 38 psig – Prior to all compressors being shut down (3 min)

- Phase 2 – 38 to 80 psig – System equalization and increase in suction pressure (30 min)

- Phase 3 – 80 psig to 7 psig – Consistent decrease in suction pressure (267 min)

The pressure changes during Phase 2 and Phase 3 were assumed to be constant (linear). Calculations were performed using the average pressure during each phase.

Significance

The cause of the release appeared to be the first broken bolt on the suction strainer cap. The mechanical integrity records were reviewed in order to determine when the bolt broke, and whether it was identified by the inspecting contractor.

A mechanical integrity inspection report from early 2020 identified the broken bolt and recommended that it be replaced. However, the report summary also indicated that “no issues were found”, which was misleading. Reportedly, the inspecting contractor did not verbally communicate the need to replace the broken bolt to the facility.

In the end, it was determined that the facility did not properly review the mechanical integrity report when it was delivered. Although inspection reports may sometimes be confusing or contain an overwhelming amount of information, it is important to ensure each recommendation is reviewed, and addressed accordingly.

Leave a Reply