Relief Valves Discharging Back into a Refrigeration System

ANSI/IIAR 2-2014 §15.6 outlines the requirements for providing Hydrostatic Overpressure Protection. In situations where thermal hydrostatic expansion of trapped liquid ammonia could occur, hydrostatic protection must be provided. Per ANSI/IIAR 2-2014 §15.6.1,

Protection against overpressure due to thermal hydrostatic expansion of trapped liquid ammonia shall be provided for equipment and piping sections that can be isolated and can trap liquid ammonia in an isolated section in any of the following situations:

- Automatically during normal operation.

- Automatically during shutdown by any means, including alarm or power failure.

- During planned isolation for standby or seasonal conditions.

- Due to an equipment or device fault.

EXCEPTION: If trapping of liquid with subsequent thermal hydrostatic expansion is only possible during maintenance or service operations, engineering or administrative controls, or both, shall be permitted as the means of relieving or preventing overpressure.

The protection required in §15.6.1 can be provided in one of two ways:

- Provide a static relief device or check valve relieving to another part of the closed-circuit system.

- Provide an expansion compensation device.

It is well known that ammonia refrigeration relief valves must be replaced or tested at least every five (5) years. The question often arises as to whether this requirement applies to liquid-rated relief valves (e.g. Cyrus Shank 803 LQ) which discharge back into the system. IIAR Bulletin No. 110 is very clear on this subject. §6.6.3 states that “Relief devices discharging into another part of the closed-loop refrigeration system are not subject to the relief valve replacement practices.” Taken at face value, Bulletin No. 110 clearly exempts hydrostatic relief valves which discharge back into the system from being replaced every five (5) years. However, the National Board Inspection Code also speaks to the subject of relief valve replacement, essentially requiring that all ASME relief valves used in refrigeration service be tested or replaced every five (5) years.

2015 National Board Inspection Code §2.5.8(f)

Frequency of test and inspection of pressure relief devices for pressure vessel and piping service is greatly dependent on the nature of the contents and operation of the system and only general recommendations can be given. Inspection frequency should be based on previous inspection history. If valves are found to be defective or damaged by system contents during inspection, intervals should be shortened until acceptable inspection results are obtained. Where test records and/or inspection history are not available, the inspection frequencies in Table 2.5.8 are suggested.

| Service | Inspection Frequency |

| Steam | Annual |

| Air and clean dry gases | Every three years |

| Pressure relief valves in combination with rupture disks | Every five years |

| Propane, refrigerant | Every five years |

| All others | Per inspection history |

Most of the ammonia refrigeration industry follows IIAR Bulletin No. 110 and pays little attention to National Board Inspection Code. The bold text below shows an example of how I have handled this issue when writing a recommendation for a 5-Year Mechanical Integrity Inspection Report:

Pressure relief valves providing hydrostatic protection to the screw compressor oil coolers have not been replaced since their initial installation. 2015 National Board Inspection Code §2.5.8 requires that all ASME pressure relief valves be tested or replaced every five (5) years. IIAR Bulletin No. 110 [June 19, 2007 Revision] §6.6.3 includes the following exception: Relief devices discharging into another part of the closed-loop refrigeration system are not subject to the relief valve replacement practices. Given the contradiction between NBIC and IIAR Bulletin No. 110, consideration should be given to replacement of the above mentioned valves.

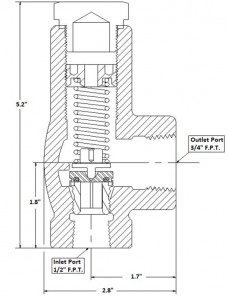

In summary, this is a classic case of competing RAGAGEPs. I believe there is some flexibility in choosing how to address this type of scenario. It is worth mentioning that if hydrostatic relief protection it needed on a section of pipe or other non-ASME equipment, a factory-set relief regulator (e.g. Parker A2CK) could be used in lieu of an ASME relief valve. It this type of installation, the National Board Inspection Code requirements would not apply since the overpressure device is not certified by ASME.

Leave a Reply