Locating Emergency Eyewash and Safety Showers

This is an update to a blog that was originally posted on 1/20/15. You can read the original blog here.

Question: Where am I required to install emergency eyewash and safety showers?

Answer: Both CalOSHA and FedOSHA require eyewash and safety showers in “all work areas where, during routine operations or foreseeable emergencies” an employee’s eye or body “may come in contact with a substance which is corrosive or severely irritating to the skin” [Title 8 CCR §5162(a) and (b)]. FedOSHA’s prescriptive requirements pretty much end there, but CalOSHA goes on to require that emergency eyewash and shower equipment must:

- meet the necessary requirements of ANSI Z358.1 (see section below for a summary)

- be plumbed or self-contained. Personal eyewash units may support plumbed or self-contained units, but may not be used in lieu of them. [Title 8 CCR §5162(a)]

- be in accessible locations that require no more than 10 seconds for the injured person to reach [Title 8 CCR §5162(c)]. ANSI/ISEA Z358.1. §B5 clarifies that “the average person covers a distance of approximately 55 ft. in 10 seconds when walking at a normal pace.“

- be activated at least monthly to flush the line and to verify proper operation. [Title 8 CCR §5162(e)]

Here are some highlights of what ANSI/ISEA Z358.1-2014 Emergency Eyewash and Shower Equipment requires:

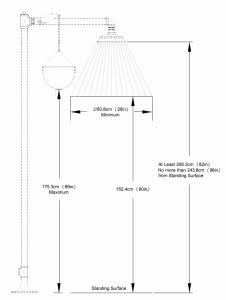

- Emergency showers must be capable of delivering flushing fluid at a minimum of 75.7 liters per minute (20 gpm) for a minimum of 15 minutes. If shut off valves are installed in the supply line for maintenance purposes, provisions shall be made to prevent unauthorized shut off. [ANSI/ISEA Z358.1 §4.1.2]

- Emergency eyewash equipment must be capable of delivering flushing fluid to the eyes not less than 1.5 liters per minute (0.4 gpm) for 15 minutes. [ANSI/ISEA Z358.1 §5.1.6]

- Emergency eyewash and showers must deliver tepid fluid [ANSI/ISEA Z358.1 §4.5.6, §5.4.6]. Tepid is defined as 60-100ºF [ANSI/ISEA Z358.1 §3]. Pipes exposed to extreme hot/cold temperatures will require insulation to satisfy this requirement.

- Emergency eyewash and showers must be located on the same level as the hazard, and the path of travel must be free from obstructions [ANSI/ISEA Z358.1 §4.5.2, §5.4.2]. This means if ammonia pipe and equipment is located on a roo,f an eyewash and shower will also be required on the same level (roof).

- Emergency eyewash and showers must be located in a highly visible area that is well lit [ANSI/ISEA Z358.1 §4.5.3, §5.4.3]

- Emergency eyewash and showers must be inspected annually to ensure the requirements list above are being satisfied [ANSI/ISEA Z358.1 §4.6.5, §5.5.5]. This is an often neglected requirement, as most people are familiar with the OSHA required monthly test, but are not performing the thorough annual evaluation.

In addition to the general OSHA and ISEA requirements listed above, ANSI/IIAR 2-2021 §6.7.2 requires that “A minimum of one eyewash /safety shower unit shall be located outside the machinery room and shall be no further than 55 ft. from the outside of the machinery room door.“.

For an ammonia refrigeration facility, the bottom line is that if you have one eyewash and shower installed outside the machinery room and believe that you are compliant, you are most likely wrong. Perform an inspection to ensure that additional emergency eyewash and shower equipment is available throughout your facility as we’ve outlined. For more information check out the following resources:

Leave a Reply