Ammonia Release | Service Valve Hole

Summary

In June 2016, a hole developed in the nipple of a ½” service valve, resulting in a release of 1,224 lbs of ammonia. The service valve, installed on a liquid transfer vessel, began leaking liquid ammonia into the machinery room.

Incident Description

Long-term, chronic corrosion caused a 1.5 mm hole to develop in the nipple of the 1/2″ service valve on a Liquid Transfer Vessel. Click here to see a video of the ammonia leak in action.

Release Calculation

The leak occurred in two (2) phases which were analyzed independently. Phase 1 of the leak spans from the beginning of the leak to the time when the liquid transfer vessel was isolated. Phase 2 of the leak spans from the isolation of the liquid transfer vessel to the end of the leak. The duration of Phase 1 was approximately 5 hours, and the duration of Phase 2 was approximately 9 hours.

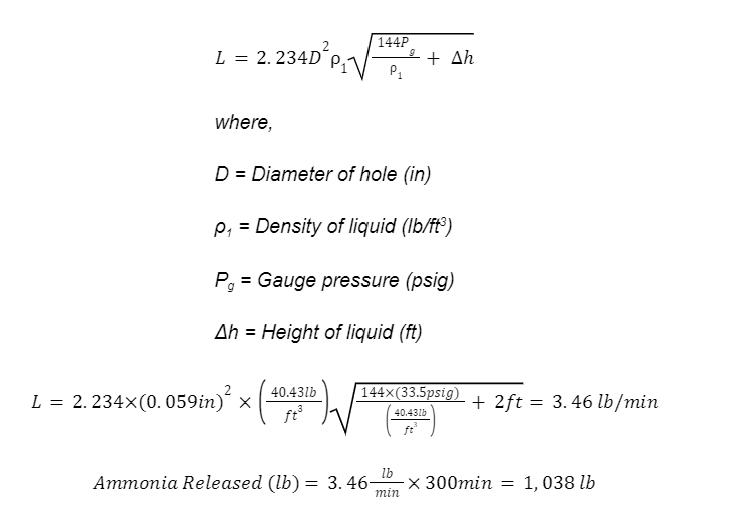

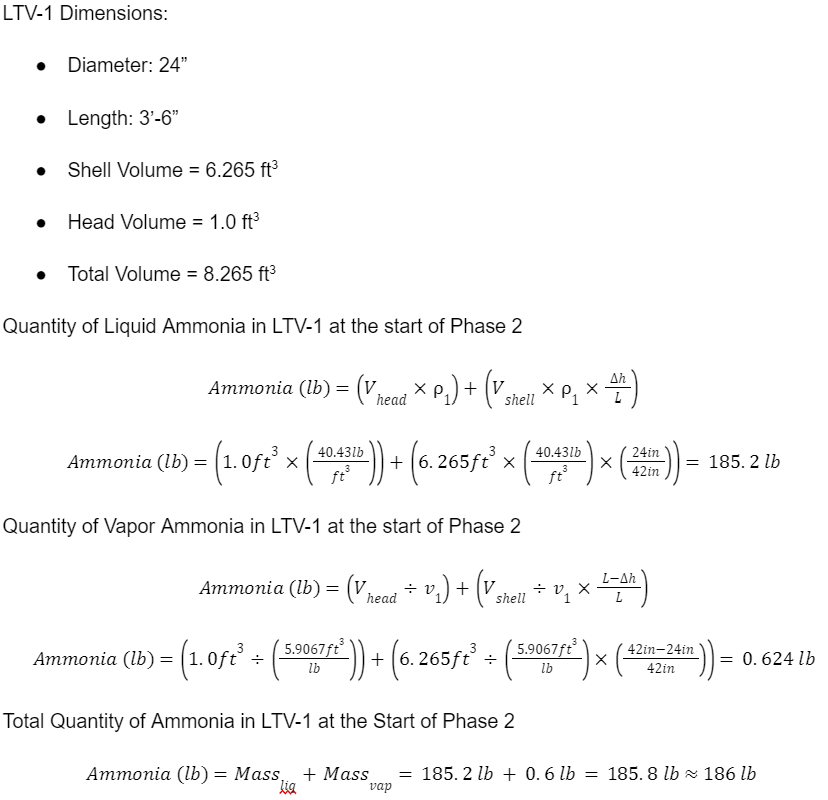

The amount of ammonia released during Phase 1 was calculated to be 1,038 lbs, and the amount calculated during Phase 2 was 186 lbs. Excerpts from the calculations are shown below.

Phase 1 Analysis

Dow Chemical Exposure Index Guide, 1st Edition – Equation 2B (Page 12)

Phase 2 Analysis

Total Ammonia Released

Significance

ANSI/IIAR 6-2019 §10.1(b) & §11.1(a) instructs to “Visually inspect metal surfaces for pitting or surface damage”. As illustrated by this incident, the formation of pits can result in a serious ammonia leak. Liquid transfer vessels and piping are particularly susceptible to corrosion and pitting due to the constant freezing and thawing cycle of the piping and vessel. Annual inspections of pipe/vessel corrosion is an important aspect of a maintenance program and should not be neglected.

Leave a Reply