Ammonia Release | Relief Valve Termination (Intercooler)

Summary

In September 2014, the termination of a relief valve to the atmosphere resulted in a release of approximately 2,700 lbs of ammonia. During the release, a roof-mounted exhaust fan pulled ammonia vapor into a highly populated room in the processing facility which exposed 34 employees to ammonia.

Incident Description

One of the relief valves installed on the Intercooler lifted when an operator repeatedly attempted to start a booster compressor when the intercooler was in a high level condition. It is estimated that the relief valve remained open for between 5 and 15 minutes. The relief vent pipe terminated approximately two feet above the roof near four exhaust fans for a processing room. At the time of the release, one of the fans was operating while the other three were off. The fans that were off acted as make-up air openings and allowed some of the ammonia vapor to be pulled into the building.

Release Calculation

At the time of the relief valve lifting, the intercooler was in a high level condition and full of liquid. Based on the high liquid level, it is possible that liquid ammonia was released through the relief valve. Therefore, calculations were performed for the scenario of a vapor-only release, a liquid-only release, and an average of the two.

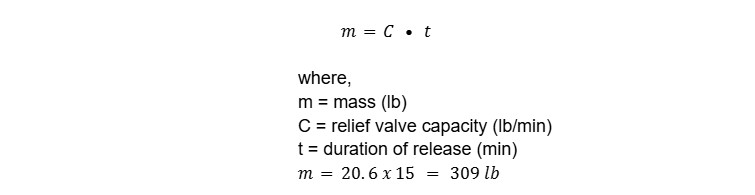

Vapor-Only Calculation

Calculating the amount of ammonia vapor released was done by utilizing the rated capacity of the relief valve. The Intercooler was equipped with a Cyrus Shank 803 150 psig relief valve which has a rated capacity of 26.7 lb/min (air), which is 20.6 lb/min (ammonia).

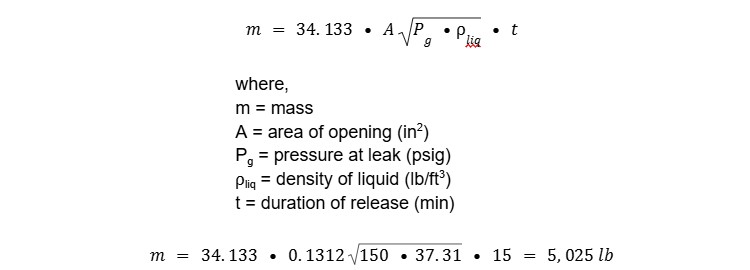

Liquid-Only Calculation

To assess the liquid-only release scenario, the equation below was adapted from the Chemical Exposure Index Guide published by the Dow Chemical Company.

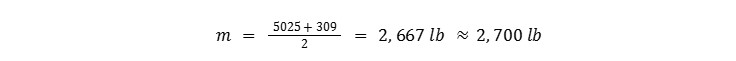

50% Liquid, 50% Vapor Calculation

The liquid/vapor mixture calculation was performed by simply averaging the two calculations.

As many factors to this release were unknown, additional calculations were performed and summarized in the table below. The release calculation report concluded that the release was approximately 2,700 lbs, but included the table below to demonstrate the various possibilities.

| Duration | Vapor Released (lb) | Liquid Released (lb) | ½ Vapor, ½ Liquid (lb) |

| 5 min | 103 | 1675 | 889 |

| 10 min | 206 | 3350 | 1778 |

| 15 min | 309 | 5025 | 2667 |

Significance

Many errors were made that eventually resulted in this incident. The configuration of the relief valve termination piping, however, is the one worth examining.

IIAR 9-2020 §7.4.2.1 states that “The termination of pressure relief device discharge piping relieving to the atmosphere shall not be less than 15 ft (4.6 m) above grade and not less than 20 ft (6.1 m) from windows, ventilation intakes, or exits.”

Additionally, §7.4.2.1 addresses the height of discharge termination points above roofs. “The discharge termination from pressure relief devices relieving to atmosphere shall not be less than 7.25 ft (2.2 m) above a roof that is occupied solely during service and inspection. Where a higher adjacent roof level is within 20 ft (6.1 m) horizontal distance from the relief discharge, the discharge termination shall not be less than 7.25 ft (2.2 m) above the height of the higher adjacent roof.”

The height and location of the relief vent termination point was a contributing factor to the employee ammonia exposure. If the termination point had been 20 feet away from the ventilation intake and 7.25 feet above the adjacent roof, ammonia vapor would not likely have been pulled into the building through the exhaust system.

Leave a Reply