Piping Hangers and Supports | IIAR Standards and Guidance Documents

Ammonia pipe supports are a crucial component to the construction of a refrigeration system. Inadequate pipe supports could lead to an ammonia release in the event of an earthquake, prolonged vibration, or physical impact. Many of IIAR’s standards and guidance documents provide helpful clarification regarding how ammonia piping should be supported and secured.

Design of Pipe Supports

ANSI/IIAR 2-2021

General requirements for supports include §5.11.4 which states that “Designers shall provide documentation that defines the basis for the support design including the anticipated loads, demonstration that the support design is adequate for the anticipated loads, and that the supports meet or exceed the equipment manufacturer’s recommendations.”

Section 13.4 of ANSI/IIAR 2-2021 specifically addresses requirements for piping, hangers, supports, and isolation:

- 13.4.1 *Piping hangers and supports shall carry the weight of the piping and any additional expected loads.

- 13.4.2 *Refrigerant piping shall be isolated and supported to prevent damage from vibration, stress, corrosion, and physical impact.

- 13.4.3 Anchors, their attachment points, and attachment methods shall be designed to support applied loads.

- 13.4.4 For insulated piping, supports shall be designed or the insulation shall be selected to avoid damage to the insulation from compression.

ANSI/IIAR 9-2020

Standard 9 does not contain as many details as Standard 2 and only requires “Piping, tubing, and equipment shall be supported to prevent excessive vibration and movement [§7.2.7.1]”

ANSI/IIAR 4-2020

This standard details requirements for the installation of a new ammonia system, or new components. While this standard does refer back to the pipe support requirements of ANSI/IIAR 2-2021, it also contains the following:

- 6.1.2 Piping support systems shall be installed to retain pipe within the support. Pipe shall not be welded to supports except where permitted by ASME B31.5.

- 6.1.2.1 *Pipe-retaining methods permitted include the use of tabs, external guides, and chocks.

IIAR Ammonia Refrigeration Piping Handbook

The IIAR Ammonia Refrigeration Piping Handbook is a guidance document and is not included in IIAR’s suite of standards. As such, it uses informative language like “may, should, it is recommended” etc.

The following guidance is included in the document:

- Adequate bracing should be provided considering the possible sway loads resulting, for example, from piping contents inducing pipe movement. [pg. 2-9]

- Piping is sometimes secured to the roof stands using U-bolts and as such are typically applied to every second or third stand. [pg. 2-10]

- It is good engineering practice to apply cross bracing between pipe stands to minimize sway. Cross bracing is also applied between every second or third set of stands, like U-bolts. [pg. 2-10]

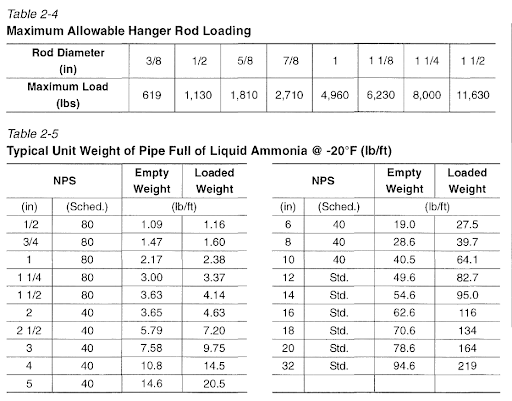

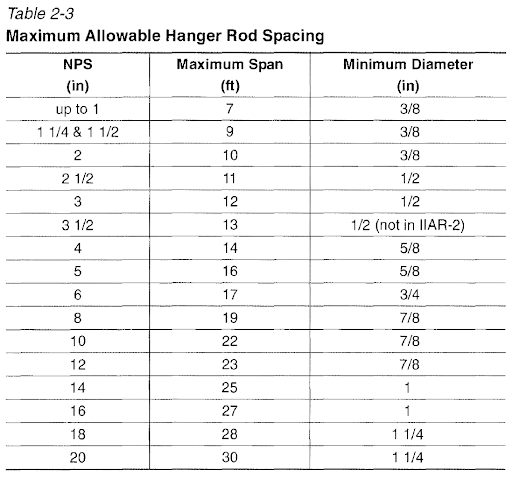

Additionally, the following tables are provided as helpful design tools:

Table 2-3 can also be located in ANSI/IIAR 2-2021 Appendix F.

Inspection of Pipe Supports

ANSI/IIAR 6-2019

ANSI/IIAR 6-2019 is the standard for inspection, testing, and maintenance of ammonia refrigeration systems. Table 11.1 provides the following inspection items regarding pipe supports:

- Visually inspect supports for cracks and degradation (Annually)

- Visually inspect mounting bolts are in place (Annually)

- Visually inspect piping for indications of movement (Annually)

- Visually inspect seismic joints and restraints (Annually)

- Visually inspect piping supports are in place and for indications of degradation that could impede their ability to provide continued support of the piping as designed (Annually)

Additional Reference

For more information regarding pipe supports and seismic restraint, refer to:

- ASHRAE Practical Guide to Seismic Restraint Second Edition

- ASCE/SEI 7-2016 Minimum Design Loads and Associated Criteria for Buildings and Other Structures

- MSS-SP-58-2018 Pipe Hangers and Supports – Materials, Design, Manufacture, Selection, Application, and Installation

Leave a Reply