Q&A | Ammonia Pipe Labels

Question: I’ve heard that the ammonia pipe labeling requirements have changed. Is that true?

Answer: Yes and No. It is true that IIAR updated Bulletin No. 114 Identification of Ammonia Refrigeration Piping and System Components in March 2014. The update includes a fundamental change that we will address in this blog. Before doing that, however, it is important that we unpack the phrase ammonia pipe labeling requirements. In order to determine if the requirements have changed, we must first be clear as to what is (or was) required. There are two (2) important standards that we must unpack to correctly answer this question.

- ASME A13.1-2007 Scheme for the Identification of Piping Systems

- ANSI/IIAR 2-2008 Addendum B Equipment, Design, and Installation of Closed-Circuit Ammonia Mechanical Refrigerating Systems

ASME A13.1-2007

ASME A13.1 is a little-known consensus standard that applies to all industries (not-specifically ammonia). As such, there are no specific references to ammonia, refrigeration, etc. within ASME A13.1. Here are a few highlights worth knowing:

- The purpose of ASME A13.1 is to “establish a common system to assist in identification of hazardous materials conveyed in piping systems and their hazards when released in the environment.”

- A legend for pipe identification is required. “Positive identification of the contents of a piping system shall be by lettered legend, giving the name of the contents in full or abbreviated form (see Table 1). Arrows shall be used to indicate direction of flow. Where flow can be in both directions, arrows in both directions shall be displayed. Contents shall be identified by a legend with sufficient additional details such as temperature, pressure, etc., as are necessary to identify the hazard.”

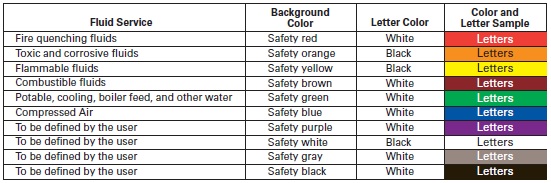

- Pipes must be marked by colors to assist in distinguishing them from each other. “Pipe color should be used to identify the characteristic hazards of the contents.” The recommended colors in ASME A13.1 are:

- Since ammonia would be classified with the Toxic and corrosive fluids the appropriate pipe/label color would be ORANGE.

ANSI/IIAR 2-2008 Addendum B

IIAR 2 is a design and installation standard which is written specifically for the industrial ammonia refrigeration industry. ANSI/IIAR 2-2008 Addendum B §10.5 requires that “all piping mains, headers and branches shall be identified as to the physical state of the refrigerant (that is, vapor, liquid, etc.), the relative pressure level of the refrigerant, and the direction of flow. The identification system used shall either be one established as a standard by a recognized code or standards body or one described and documented by the facility owner.”

Attempting to dove-tail the requirements of ASME A13.1 and ANSI/IIAR 2-2008 Addendum B, one would conclude that the recommended ammonia pipe label would include the following characteristics:

- Be ORANGE in color

- Indicate the physical state of the ammonia

- Indicate the relative pressure of ammonia

- Include a flow direction arrow

So that is what everyone has been doing, right? Not exactly.

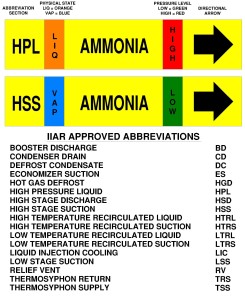

As it turns out, IIAR Bulletin No. 114 has been the primary reference source for selecting ammonia pipe labels even though by the very fact that it is a Bulletin (not a Standard) its content should have been viewed as Informative and not Normative. However, since the 1991 edition of IIAR Bulletin No. 114 was written, nearly all of the ammonia refrigeration industry has followed Bulletin No. 114 and ignored (or been unaware of) ASME A13.1. The recommended ammonia pipe label in IIAR Bulletin No. 114 (1991 Edition) was YELLOW in color as illustrated below:

In order to more closely align with ASME A13.1, in March 2014 IIAR revised Bulletin 114, to swap the use of ORANGE and YELLOW in the recommended pipe label.

Now returning to the original question asked, the requirements have not changed, but a significant Guidance Document (IIAR Bulletin No. 114) has.

So does this mean that you have to replace all of your YELLOW ammonia pipe labels now that you are aware of this? Absolutely not. Section 1 of ASME A13.1 clearly states that “Existing schemes for identification shall be considered as meeting the requirements of this Standard if: (a) such schemes are described in writing; (b) employees are trained as to the operation and hazards of the piping system”.

So what does this change mean for anybody? Does new equipment need to follow updated guidelines?

Good question! The most important factor in labeling is consistency, so if your facility follows the old labeling scheme (YELLOW labels), then I would recommend continuing with that scheme. In other words, don’t mix the new and the old.

Per ASME A13.1 ““Existing schemes for identification shall be considered as meeting the requirements of this Standard if: (a) such schemes are described in writing; (b) employees are trained as to the operation and hazards of the piping system”.

What is the maximum distance between pipe markers on a single line? also does the line have to be marked after every pipe turn?

According to IIAR Bulletin No. 114 §5.0:

“Piping markers shall be located as follows:

a. before and after a change in piping direction; when piping terminates at equipment and is within 24” of a marker or when piping changes direction more than once and is within 24” of a marker, it is not necessary to place an additional marker between the directional changing elbows or the termination point at equipment.

b. before and after piping penetrations of walls, ceilings and floors,

c. on extended horizontal or vertical runs of pipe, with a maximum spacing of 40 feet between markers, in order to provide positive identification, and

d. at least once on the piping in every area through which the refrigeration piping

passes.”

How is the length of each color field determined? For instance, is there a specified length for the HSS or the HPL (shown in the example)? Is there a specific size for the LIQ or the HIGH?

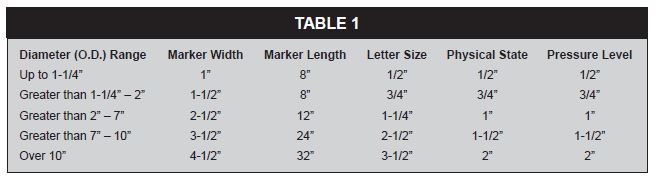

IIAR Bulletin No. 114 includes a table (Table 1) in §4.1.8: