Ammonia Release | Stress Cracking

Summary

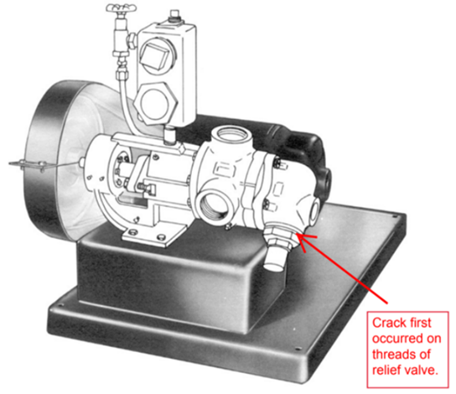

In August 2016, the sudden breaking of a valve on an ammonia pump resulted in a release of 34-284 lbs of ammonia. The root cause was determined to be a stress crack that formed at the threads of a valve, ultimately leading to the top of the valve shearing off.

Incident Description

The ammonia refrigeration system at the food processing/cold storage plant was configured with a liquid transfer vessel and transfer pump. The valve in question was located in the pump bypass piping.

Investigation into the incident revealed that the stress crack formed from years of frosting and thawing cycles. The cycles allowed water to freeze and expand, then contract as the ice melted. This phenomenon is commonly seen on roadways where freezing and thawing of water results in crack formation.

Release Calculation

Calculating the amount of ammonia released was dependent on the liquid level inside the Liquid Transfer Vessel when the failure occurred. At the time of the leak, a technician was able to quickly isolate the vessel. Therefore, the calculation assumed that no additional ammonia entered the vessel once the leak began. However, the initial liquid level in the vessel at the start of the leak was unknown, so multiple calculations were performed.

Liquid Transfer Vessel Specifications

Orientation: Vertical

Diameter: 24”

Length: 3’-6”

NH3 @ 85% full: 284 lbs

NH3 @ 10% full: 34 lbs

The vessel would have contained 284 lbs of ammonia at a maximum liquid level. At a minimum liquid level, it would have contained 34 lbs. Therefore, the release was reported as a range of 34-284 lbs of ammonia.

Significance

IIAR 6-2019 §5.6.8 states that “Equipment and piping shall be kept free from excessive ice buildup.” Visual inspection of equipment is crucial for ensuring proper system maintenance. While a stress crack inside a valve may not be visible during daily rounds, special attention should be paid during maintenance activities to areas that experience frequent frosting and thawing. Corrosion and crack formation are often more likely to develop in these conditions, so liquid transfer vessels/pumps should be closely monitored.

Leave a Reply