Pipe Plugs and Caps in Ammonia Refrigeration Systems

Question: Are oil drain valves and service valves required to be plugged or capped when not in use?

Answer: Yes. All shut-off valves connecting equipment or piping to the atmosphere must be plugged, capped, blanked, or locked closed when they are not in use.

ANSI/IIAR 2-2021 §13.3.2.6 states “Shut-off valves connecting ammonia-containing equipment or piping to atmosphere shall be capped, plugged, blanked, or locked closed during shipping, testing, operating, servicing, or standby conditions when they are not in use.”

In addition, IIAR Standards 2 and 9 both address the importance of plugging or capping refrigeration system charging connections when they are not in use. Refer to ANSI/IIAR 9-2020 §7.2.8.1 and ANSI/IIAR 2-2021 §5.12.2.

In September 2012, a facility in California had a catastrophic ammonia leak that led to one employee death. The leak started when an employee mistakenly opened an oil drain valve that was not capped or plugged. The missing cap/plug was a contributing factor in the death.

This story illustrates the importance of caps and plugs in ammonia refrigeration systems. Even if a shut-off valve is present upstream of an oil drain/service valve, this may not necessarily prevent an accidental ammonia release. Installing caps and plugs on all ammonia valves connected to the atmosphere is an important safety feature in an ammonia refrigeration system.

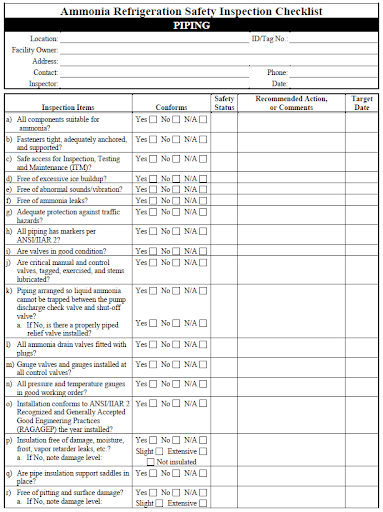

Mechanical integrity inspections are an excellent time to inspect the system for this particular deficiency. The ANSI/IIAR 6-2019 Appendix B Piping Checklist includes an inspection item that asks “All ammonia drain valves fitted with plugs?” Ensure any cap or plug deficiencies are addressed promptly.

Leave a Reply