Ammonia Release | Band Saw to a Live Line

Summary

In October 2021, a contractor accidentally cut into a live ammonia pipe, resulting in the release of approximately 419 lbs of ammonia. Due to a general lack of labeling, the live pipe was confused for the decommissioned pipe that was intended to be cut out of the system.

Incident Description

A contractor was performing work on the refrigeration system in the machinery room. One of the pipes in the machinery room was scheduled to be removed as a part of a system renovation. The contractor cut into the wrong pipe with a band saw which happened to be a live 1-½” thermosyphon return (TSR) line.

The contractor was standing on a ladder at the time and was luckily able to escape without being injured. The machinery room ventilation system was turned on and a portion of the system was isolated from outside the machinery room.

Release Calculation

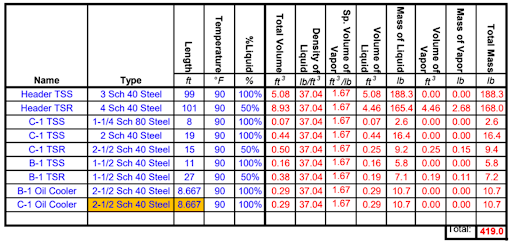

The amount of ammonia released was calculated by determining how much ammonia is normally contained in the thermosyphon piping. Based on the pipe diameters, lengths of piping, temperature of ammonia, and percent liquid, the total amount of ammonia inside the associated thermosyphon piping was calculated to be 419 lbs.

Significance

Pipe labeling is extremely important and can help prevent an accidental ammonia release. Equally as important, is developing detailed decommissioning procedures. A detailed procedure should clearly identify which pipes need to be cut from the system, and instructions to tag these pipes and ensure they are pumped down completely.

It should be noted that the contractors were able to greatly reduce the amount of ammonia released by isolating a segment of the system from outside the machinery room. This was made possible by having accurate P&IDs to reference. Good documentation and labeling are often underestimated in their value. This incident illustrates the importance of both of these Process Safety Management cornerstones.

Leave a Reply