P&IDs and MOCs (Part 6)

A great way to maintain P&ID accuracy is to implement an effective management of change (MOC) program. If used correctly, an MOC will initiate modifications to PSM elements that require attention when a facility or process change takes place. Assuming the scope of an MOC includes process equipment, the P&IDs will require amendment. Here is some food for thought when updating P&IDs during the MOC process:

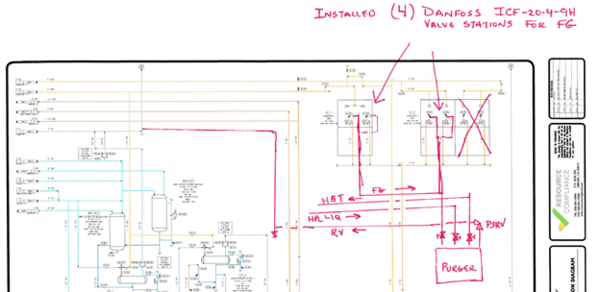

- Red-line: Prior to implementing changes, it may be prudent to red-line the existing P&ID by hand with a red pen.

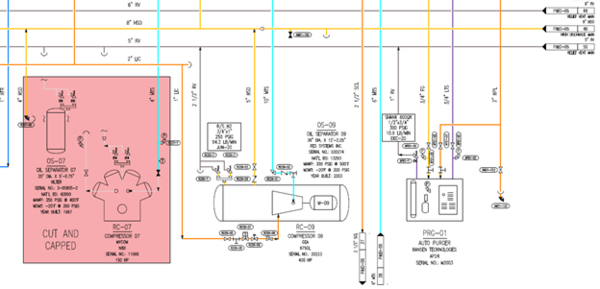

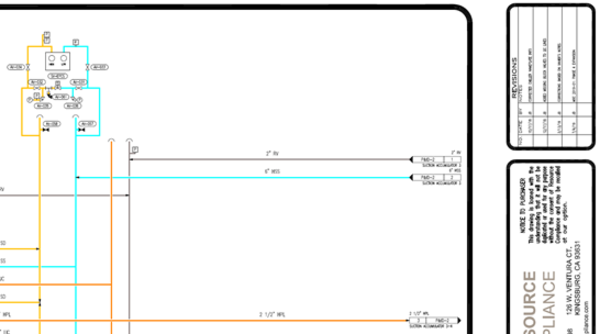

This method of depicting alterations is particularly effective for smaller changes to process piping and equipment. After the project is completed, the red-lined P&IDs should be audited and so that the ‘as built’ drawings can be finalized using AutoCAD. - Decommissioned Equipment: If the MOC involves disconnecting equipment from the system, it may be wise to continue to depict the equipment on the drawing. This will save time later if the equipment is reconnected. When this occurs, we suggest clearly annotating the equipment as displayed below.

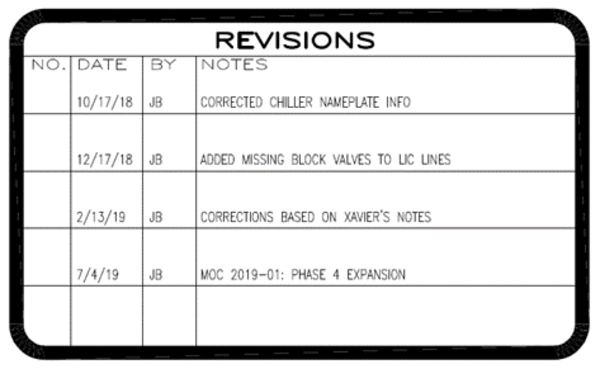

- Revision History: As with other requirements, the mantra “if it isn’t documented, it didn’t happen” applies to P&IDs. With that in mind, make sure that all P&ID modifications are recorded.

A common way to capture P&ID changes is by including a “revision history” section on each page of a P&ID title block.

This is Part 6 of a series on P&IDs. You can access previous blogs in this series below:

- Part 1: Introduction to P&IDs

- Part 2: P&IDs and SOPs

- Part 3: P&IDs and PHAs

- Part 4: P&IDs and Emergencies

- Part 5: P&IDs and Training

Leave a Reply