Introduction to P&IDs (Part 1)

It has been a few years since we last wrote about P&IDs. While most operators recognize that P&IDs are important, we often find there is confusion when it comes to using the diagrams in day-to-day operation. In the next few blogs, we will provide practical guidance to enable operators at PSM facilities to utilize P&IDs as part of their normal routine. But first, here’s a quick overview on these important drawings.

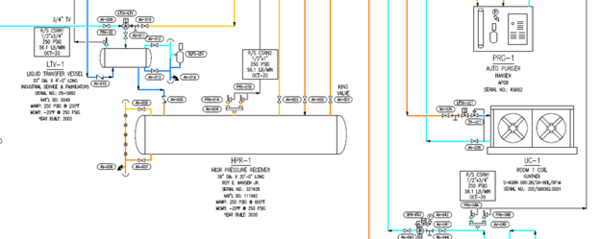

What is a P&ID? A P&ID is a diagram that depicts the interconnection of process equipment and instrumentation. The term “P&ID” is an acronym for “Piping and Instrumentation Diagram”. As a drawing, a P&ID includes all process equipment, interconnecting pipes, manual valves, control valves, and process-related instrumentation as necessary to fully represent and understand the system.

A P&ID of a small system may fit on a single page, while a complex chemical process may be hundreds of pages.

Why are P&IDs required? P&IDs are a fundamental requirement of the RMP, PSM, and CalARP regulations. Specifically, when developing and organizing process safety information, a facility must ensure that the information pertaining to the equipment in the process include P&IDs. Additionally, P&IDs are an essential tool to any operator who seeks to fully understand his system. These drawings are particularly important for ammonia refrigeration systems, and IIAR standards encourage P&IDs to be developed as part of the system documentation in the non-mandatory Appendix B of ANSI/IIAR 9-2020.

Are P&IDs that important? P&IDs are the cornerstone of PSM process safety information (PSI). How is relief system design verified? How are inventory calculations performed? What compressor/condenser capacity is available? Oftentimes, this information is available through the P&IDs. If your system P&IDs are accurate, there is high likelihood that your PSI program will be in good shape. On the other hand, if your P&IDs are incorrect, your PSI is almost guaranteed to be riddled with inconsistencies.

Where do P&IDs come from? P&IDs are typically developed by the engineering team when a system is initially designed. After installation, the diagrams can be audited and corrected if inaccuracies are observed. Once corrected, the P&IDs are considered ‘as built’ and fully reflect the system configuration. Unfortunately, many P&IDs have become outdated or lost altogether due to system modifications or changes in facility management. When changes to a system are vast or the drawings are misplaced, P&IDs can be developed from scratch, which is a labor intensive and costly endeavor.

How do I use P&IDs? We’re glad you asked this question. Over the next several blogs we’ll address how to use P&IDs in conjunction with SOPs, PHAs, emergencies, training, and MOCs.

Leave a Reply