PSI Explained: Maximum Intended Inventory

One often discussed requirements within PSI, is the documentation concerning Maximum Intended Inventory. The meaning of maximum intended inventory is exactly what the words imply – the maximum chemical inventory that a facility intends to utilize (have onsite) at any time. For a transient process in which a chemical is consumed, this often corresponds to the capacity of the storage vessels within the process. For a closed-loop system (ammonia refrigeration), the maximum intended inventory is the actual inventory required to operate. Many vessels within a refrigeration system are designed to operate partially filled with liquid or completely full of vapor (e.g. oil separators) during normal operation. The maximum intended inventory is not the inventory of ammonia that could be contained if all vessels, pipe, and equipment were filled to 100% capacity with liquid as this scenario would never be “intended”. It can be time consuming to calculate the inventory contained within a refrigeration system. To give an idea of what is involved in calculating the inventory (mass) within a horizontal pressure vessel, I have included the equations necessary to perform the analysis below. Thanks to spreadsheets and software, the calculations can be performed with more ease than otherwise would be the case if forced to do the work long-hand.

Mass of Liquid

ML = VL • ρ

ML = Mass of liquid (lb)

VL = Volume of liquid (ft3)

ρ = Density of the liquid ammonia (lb/ft3)

Mass of Vapor

MV = VV / vV

MV = Mass of vapor (lb)

VV = Volume of vapor (ft3)

vV = Specific volume of ammonia vapor (ft3/lb)

Total Mass

MT = ML+MV

MT = Total mass (lb)

ML = Mass of liquid (lb)

MV = Mass of vapor (lb)

Total Volume of a Vessel

VT = 2Vh+Vs

VT = Total volume (ft3)

Vh = Volume of the head (ft3)

Vs = Volume of the shell (ft3)

Shell Volume

Vs = πD2/4 • (L-2•HD/12)

Vs = Volume of the shell (ft3)

D = Inside diameter of the vessel (ft)

L = Length of the vessel (ft)

HD = Head depth (in)

Horizontal Vessel Liquid Volume

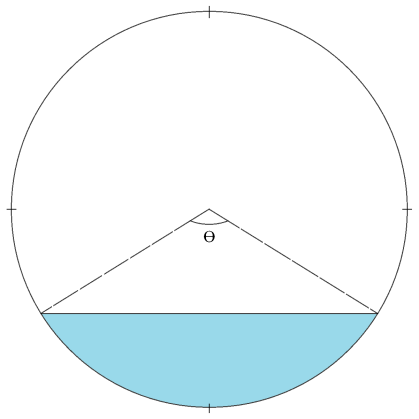

Θ = 2cos-1 (1-2x/D)

θ = Theta

x = height of liquid minus the wall thickness of the vessel (in)

D = Inside diameter of the vessel (in)

A = D2/8 • (θ – sin θ)

A = Cross sectional area of the liquid (in2)

D = Inside diameter of the vessel (in)

θ = Theta

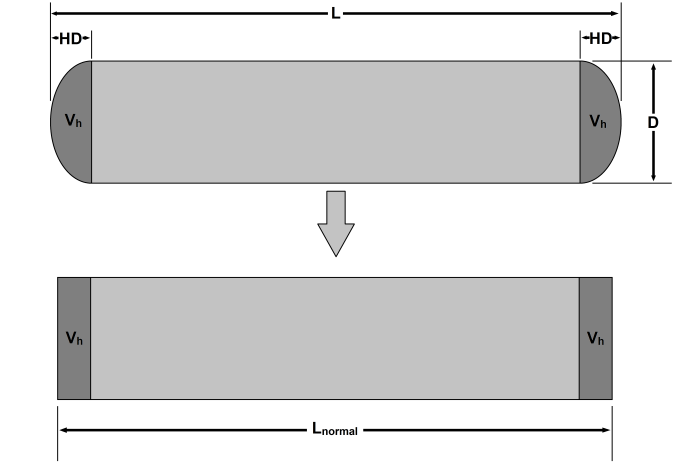

Lnormal = (L – 2 • HD/12) + 2 • (4•Vh/(π(D/12)2))

Lnormal = Normalized length of the vessel if it were a simple cylinder (ft)

L = Length of the vessel (ft)

HD = Head depth (in)

Vh = Volume of the head (ft3)

D = Inside diameter of the vessel (in)

VL = A/144 • Lnormal

VL = Volume of liquid (ft3)

A = Cross sectional area of the liquid (in2)

Lnormal = Normalized length of the vessel if it were a simple cylinder (ft)

Leave a Reply