Ammonia Detection in Non-Machinery Rooms

Question: Is ammonia detection required in rooms that contain ammonia, but are not classified as machinery rooms?

Answer: To answer this question properly, we must first consider the various occupancy classifications and refrigerant restrictions within those classifications.

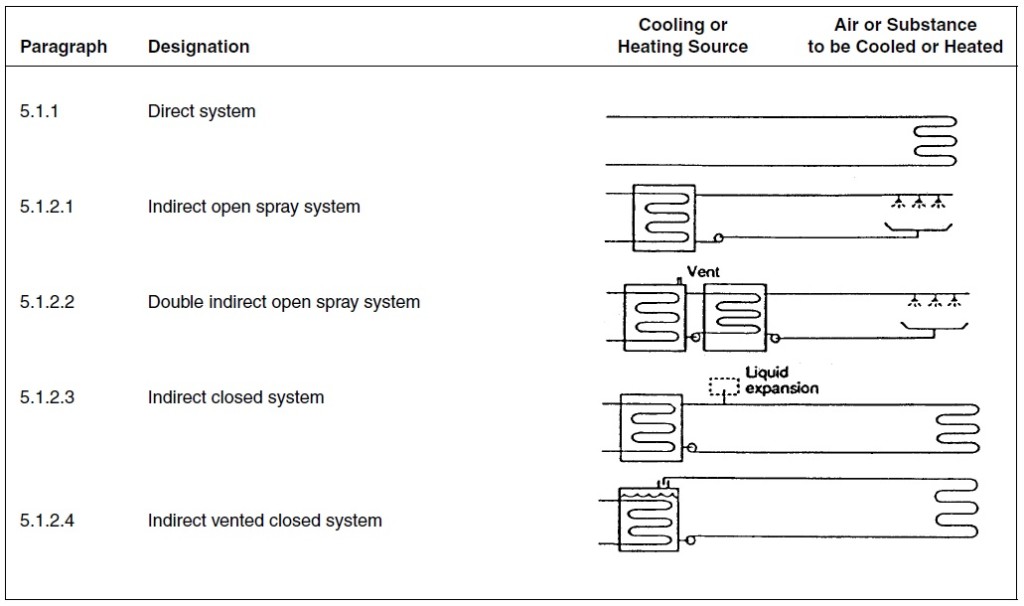

ANSI/ASHRAE 15-2013 Safety Standard for Refrigeration Systems defines two (2) main types of refrigeration systems: Direct Systems and Indirect Systems. Indirect Systems are further divided into four (4) sub-classifications for a total of five (5) possible refrigerating system types, which are illustrated below:

Typically, ammonia refrigeration systems fall into either the direct system or indirect closed system categories. An example of a direct system is a central refrigeration machinery room which supplies liquid ammonia to air-cooling evaporators (flooded, overfeed, or direct expansion) which then cool air inside a refrigerated room. An example of an indirect closed system is an ammonia system in which the only evaporator is a plate heat exchanger which is used to chill a glycol-water mixture. The cold glycol-water mixture is then used for process cooling.

Once the type of refrigeration system is determined, the system can be classified. ANSI/ASHRAE 15-2013 §5.2 has two (2) system classifications: High-Probability Systems and Low-Probability Systems. “A high-probability system is any system in which the basic design, or the location of components, is such that a leakage of refrigerant from a failed connection, seal, or component will enter the occupied space.” Direct systems and indirect open spray systems are typical high-probability systems. A low-probability system is a system that does not fit the high-probability system definition or “in which the basic design or location of the components is such that leakage of refrigerant from a failed connection, seal, or component cannot enter the occupied space.”

In addition to the system type and classification, ANSI/ASHRAE 15-2013 includes refrigerant restrictions which are dependent on the type of occupancy. Seven (7) unique occupancy types are defined in ANSI/ASHRAE 15-2013 §4:

- Institutional occupancy is a premise or that portion of a premise from which, because they are disabled, debilitated, or confined, occupants cannot readily leave without the assistance

of others. Institutional occupancies include, among others, hospitals, nursing homes, asylums, and spaces containing locked cells. - Public assembly occupancy is a premise or that portion of a premise where large numbers of people congregate and from which occupants cannot quickly vacate the space. Public assembly occupancies include, among others, auditoriums, ballrooms, classrooms, passenger depots, restaurants, and theaters.

- Residential occupancy is a premise or that portion of a premise that provides the occupants with complete independent living facilities, including permanent provisions for living, sleeping, eating, cooking, and sanitation. Residential occupancies include, among others, dormitories, hotels, multi-unit apartments, and private residences.

- Commercial occupancy is a premise or that portion of a premise where people transact business, receive personal service, or purchase food and other goods. Commercial occupancies include, among others, office and professional buildings, markets (but not large mercantile occupancies), and work or storage areas that do not qualify as industrial occupancies.

- Large mercantile occupancy is a premise or that portion of a premise where more than 100 persons congregate on levels above or below street level to purchase personal merchandise.

- Industrial occupancy is a premise or that portion of a premise that is not open to the public, where access by authorized persons is controlled, and that is used to manufacture, process, or store goods such as chemicals, food, ice, meat, or petroleum.

- Mixed occupancy occurs when two or more occupancies are located within the same building. When each occupancy is isolated from the rest of the building by tight walls, floors, and ceilings and by self-closing doors, the requirements for each occupancy shall apply to its portion of the building. When the various occupancies are not so isolated, the occupancy having the most stringent requirements shall be the governing occupancy.

Most ammonia systems are installed at facilities that would be classified as an Industrial Occupancy. There is definitely a movement towards using ammonia in commercial occupancies, but for now we will consider the industrial occupancy scenario.

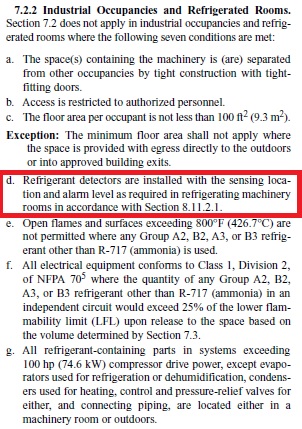

ANSI/ASHRAE 15-2013 §4.2 restricts the use of refrigerant as follows: “The concentration of refrigerant in a complete discharge of each independent circuit of high-probability systems shall not exceed the amounts shown in Table 4-1 or 4-2 of ASHRAE Standard 34,1 except as provided in Sections 7.2.1 and 7.2.2 of this standard.” For ammonia, the Occupational Exposure Limit (OEL) as listed in Table 4-1 is 25 ppm. Since a “complete discharge” of essentially every ammonia refrigeration system would result in a room concentration in excess of 25 ppm, on first glance it appears that ammonia is prohibited from being used in a non-machinery room. However, §7.2.2 contains a very critical exception:

It is beyond the scope of this blog to discuss each of the conditions in §7.2.2, however, §7.2.2(d) clearly addresses the question that we set out to answer. In order to use ammonia as a refrigerant in a “non-machinery room” in a direct, high-probability, industrial system, an ammonia detector must be installed in the space.

Let’s quickly retrace the steps we took to answer this question:

- An ammonia refrigeration system with a central machinery room that supplies air-cooling evaporators in a cold storage room is considered a direct system.

- A direct system is further classified as a high-probability system.

- Ammonia is typically used as a refrigerant in what is classified as an industrial occupancy.

- The complete discharge of a refrigeration system into a “non-machinery room” would cause the concentration in the room to exceed 25 ppm in nearly all cases.

- Therefore, ammonia is prohibited from being used in a “non-machinery room” unless seven (7) conditions are met, one of which is “refrigerant detectors are installed with the sensing location and alarm level as required in refrigerating machinery rooms…”

It is worth mentioning, that the same exceptions do not apply to commercial occupancies, which is why ammonia is not commonly used as a commercial refrigerant, except when secondary coolants are involved (indirect systems).

Leave a Reply