Q&A | NFPA 704 and Ammonia

Question: What is the correct NFPA 704 placard for an ammonia refrigeration system?

Answer: This question has caused enormous confusion in the ammonia refrigeration industry, so I will attempt to bring some clarity to the issue.

ANSI/IIAR 2-2008 Addendum B §13.1.10.4 requires that “Refrigerating systems shall be provided with approved informative signs, emergency signs, charts and labels in accordance with NFPA 704. Hazard signs shall be in accordance with the International Mechanical Code.”

Using similar language, 2015 IFC §606.7 requires that “Refrigeration units or systems having a refrigerant circuit containing more than 220 pounds (100 kg) of Group A 1 or 30 pounds (14 kg) of any other group refrigerant shall be provided with approved emergency signs, charts and labels in accordance with NFPA 704. Hazard signs shall be in accordance with the International Mechanical Code for the classification of refrigerants listed therein.”

As is clear from the the code references above, the answer to this question is contained within the International Mechanical Code (IMC).

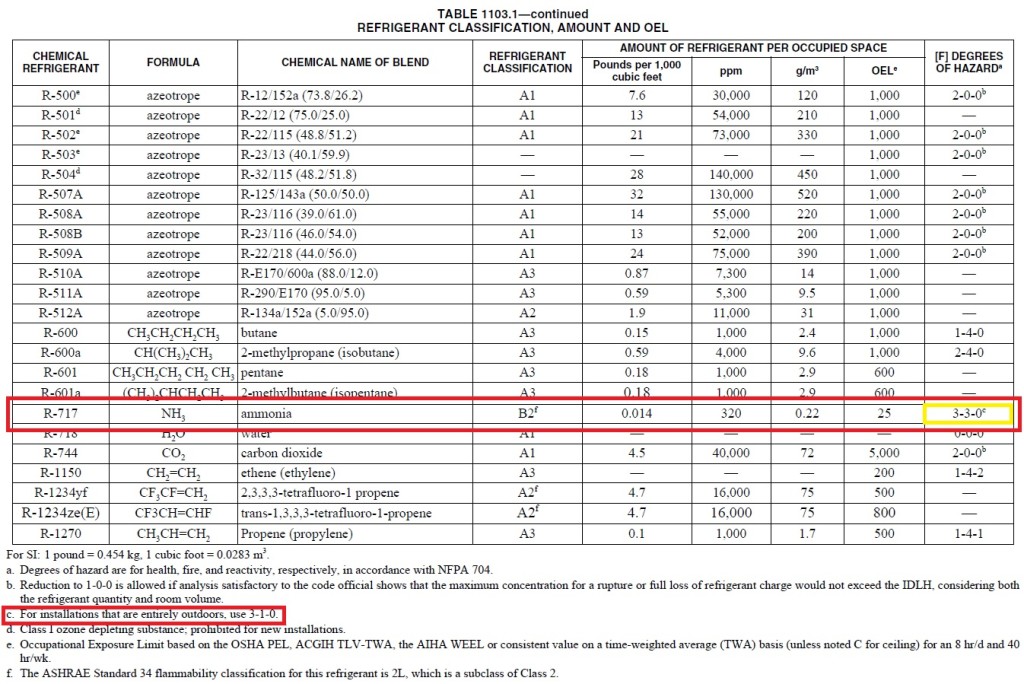

So what does IMC have to say about the NFPA hazard rankings? Table 1103.1 answers the question.

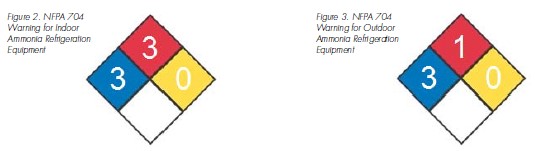

In the February 2011 issue of the CONDENSER, Jeff Shapiro clearly explains the history of NFPA 704 and how the hazard classifications became assigned to ammonia. Quoting Jeff’s article, “In most cases, NFPA 704 classifications are assigned based on the subjective judgment of persons knowledgeable in hazardous materials. However, in the case of ammonia refrigeration systems, IMC Table 1103.1 has codified the classifications by formally assigning health, fire and instability ratings of 3-3-0 (Figure 2) for indoor installations and 3-1-0 (Figure 3) for outdoor installations.”

Do you know of any Code that requires the emergency exhaust fan in amonia engine room to have back up electric source?

Good question. A backup electrical source is not required, however, ANSI/ASHRAE 15-2013 §8.12(i) and ANSI/IIAR 2-2008 Addendum B §13.3.1 both require the ventilation system to be powered “independently” of the other machinery room equipment and not subject to the emergency shutdown controls.

What about the white diamond??? Sometimes I see COR in there and sometimes I Don’t… Which is correct? I currently have 3-3-0-COR on our entry doors to our ammonia machinery room.

Terry, I have seen ammonia NFPA 704 placards with the ‘COR’ designation in the white placard a several times (including the image at the top of the blog). While I don’t think it is harmful to use this designation since ammonia behaves as a corrosive chemical on human skin, the recommended placard(s) for ammonia are depicted above (February issue of Condenser magazine) and do not have any symbol in the special hazards quadrant. It is worth pointing out that the 2017 version of NFPA 704 does not even list ‘COR’ as one of the abbreviations that belong in the white quadrant. Here is the entire text:

Chapter 8 Special Hazards

8.1 General.

8.1.1 This chapter shall address water reactivity and oxidizing properties of the materials that cause special problems or require special fire-fighting techniques.

8.1.2 Special hazard symbols shall be shown in the fourth space of the sign or immediately above or below the entire sign.

8.2 Symbols. Special hazards shall be represented by a spatial arrangement denoted by symbols always at the six o’clock position.

8.2.1 Materials that react violently or explosively with water (i.e., water reactivity rating 2 or 3) shall be identified by the letter “W” with a horizontal line through the center.

8.2.2 Materials that possess oxidizing properties shall be identified by the letters “OX.”

8.2.3 For chemicals requiring both “special hazard” symbols (i.e., w-and OX), the w- shall be displayed inside the special hazards quadrant, and the OX shall be displayed directly below or adjacent to, the special hazards quadrant

8.2.4 Materials that are simple asphyxiant gases shall be permitted to be identified with the letters “SA” and shall include the following gases: nitrogen, helium, neon, argon, krypton, and xenon.

8.2.4.1 The SA symbol shall also be used for liquefied carbon dioxide vapor withdrawal systems and where large quantities of dry ice are used in confined areas.

When provided audio visual devices to annuciated an ammonia leak detection, do they need to be supervised as you would on a fire alarm system?

When activated, ammonia detection and alarm systems must send a signal to a “monitored” location.

ANSI/IIAR 2-2014 §17.7.1 Level 1 Ammonia Detection and Alarm. Level 1 ammonia detection and alarm shall have

the following features:

1. At least one ammonia detector shall be provided in the room or area.

2. The detector shall activate an alarm that reports to a monitored location so that corrective action can be taken at an indicated concentration of 25 ppm or higher.

[Note: Sections §6.13, §17.2, §17.7.2, §17.7.3 also include similar language about alarms reporting to a “monitored location“]

Monitored is defined in Chapter 2 of the same document as “A means of continuous oversight, such as notification of staff, a third-party alarm service, or a responsible party.“