Ammonia Release | Contractor Error and Coil Failure

Summary

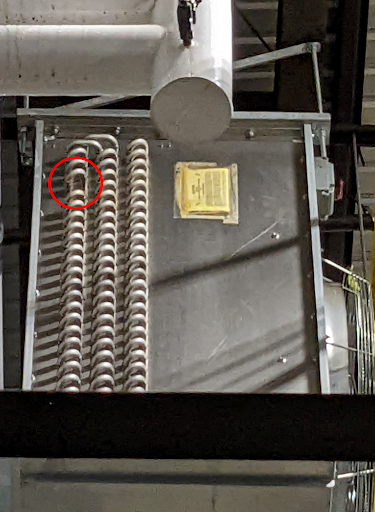

In August 2022, hydrostatic expansion occurred inside an improperly isolated evaporator coil, resulting in a release of approximately 230 lbs of ammonia. The leak occurred when one of the return tubes of the evaporator coil broke due to the overpressurization.

Incident Description

The evaporator coil (Coil 3) was recently replaced and the other two coils in the room (Coils 1-2) were left unchanged. The Coil 3 had been installed and pressure tested but was scheduled to be commissioned after the insulation contractor could complete the piping.

Days before the leak, the room was needed for product cooling. Therefore, the new evaporator liquid isolation valve was closed and the suction return valve was left slightly open to allow ammonia from the pressure test to escape. The zone was turned on with Coils 1-2 operating.

Over several days, ammonia vapor entered from the suction pipe shared with Coils 1-2. It is suspected that the vapor condensed inside the coil over time. The night of the incident, the zone went into a water defrost cycle. This raised the temperature of the coils and the liquid/vapor mix in Coil 3 rapidly expanded. Since the suction valve was slightly cracked, the ammonia could not return fast enough. This built excessive pressure, causing the coil return tube to break.

Release Calculation

The release calculation was performed under the conservative assumption that at the time of the leak, Coil 3 was completely full of liquid. It was also assumed that no additional ammonia entered the coil through the suction isolation valve.

Based on these assumptions, the amount of ammonia released was calculated using the internal volume of the evaporator. Assuming the coil was completely filled with liquid, and knowing the internal volume of the coil was 5.76 cubic feet, this corresponds to 230.2 lbs of liquid ammonia.

Significance

The contributing factors to the release appear to be a contractor error, and impatience of the facility to start cooling the room. An error was made by the contractor in not opening the suction valve enough to allow for hydrostatic expansion to occur. Reportedly, the construction crew did not consult with the refrigeration service or engineering department before adjusting the valves on the evaporator after the pressure test. Had they obtained instructions or been supervised by another department, the suction valve would have been left fully open, or fully closed after ensuring the evaporator was empty of ammonia.

The premature cooling of the room where Coil 3 was located may have been another contributing factor to the release. It is unknown whether the installing contractor was consulted before Coils 1-2 were turned on.

This incident illustrates the danger of hydrostatic expansion and the type of damage that can be caused. In order to prevent liquid ammonia from being trapped in an ammonia system, facilities should ensure that vessels are not filled beyond 85%, and purge valves are installed at valve groups where the automatic trapping of liquid can occur.

Leave a Reply