Obtaining System Documentation

It is common to find Process Safety Information documentation lacking within a PSM program. Unfortunately, this deficiency is not limited to “older” facilities, but often occurs after the installation of a new system or a new component within an existing system. To help remedy this, we have developed the following Request for Proposal (RFP) Addendum. The purpose of the RFP Addendum is to provide a template that can be used as an attachment to a Request for Proposal (RFP) when soliciting bids for an ammonia refrigeration project. We hope you find it useful.

To whom it may concern:

The purpose of this document is to describe the documentation that will be required to be supplied by the refrigeration contractor selected to perform the design and installation of the Ammonia Refrigeration Project at Company XYZ.

Company XYZ utilizes anhydrous ammonia as a refrigerant in its refrigeration system. As such, it is important that all construction performed on and around the refrigeration system comply with the requirements of the following regulations:

- California Accidental Release Prevention (CalARP) Program – Title 19 CCR, Chapter 4.5

- Federal EPA Risk Management Program (RMP) – Title 40 CFR §68

- California Process Safety Management (PSM) Program – Title 8 CCR §5189

- Federal Process Safety Management (PSM) Program – Title 29 CFR §1910.119

Company XYZ has the following minimum requirements that must be included in the scope of work proposed by your company in order to be considered for contractor selection on the Ammonia Refrigeration Project:

- Documentation that the firm(s) responsible for design and installation have at least one of the following licenses/designations:

- Refrigeration Contractor

- Professional Engineer

- Certificates of all welders

- Component inventory list for all installed components including at minimum:

- Physical description

- Nameplate data

- Year of construction

- Minimum/maximum working temperatures

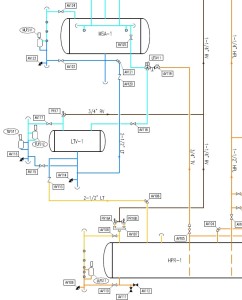

- Piping and instrumentation diagram (P&ID) of the refrigeration system

- Manufacturer’s instruction manuals for all installed components

- Piping schedules including documentation that all pipe used conforms to ASME B31.5-2013

- Manufacturer Data Reports (U-1, U-1A, and U-3 Forms) for pressure vessels and heat exchangers

- Inventory calculations for ammonia added to the refrigeration system

- Receipts for all ammonia deliveries documenting that refrigerant-grade anhydrous ammonia was used.

- Certification that the system was installed in accordance with International/Uniform/California Mechanical Code Chapter 11, International/California Fire Code Section 606, and ANSI/IIAR 2-2008 Addendum B.

- For projects involving compressors, certification that all high pressure, low pressure, oil pressure, and high temperature cutouts have been tested and found operational.

- For projects requiring ammonia detection, a functional description of the detection system and certification that ammonia detection devices have been tested and found operational.

- For projects involving ventilation, a functional description of the ventilation system including design calculations and the basis of the ventilation system design. Certification that the ventilation system was tested and found operational.

- For projects involving relief valves, the capacity selection criteria and discharge piping design basis.

- For projects involving an Emergency Pressure Control System (EPCS), a functional description of the EPCS and certification that the EPCS has been tested and found operational.

- For projects involving an emergency stop switch, a functional description of the emergency stop switch and certification that the switch has been tested and found operational.

- For projects involving high level float switches, certification that the switches have been tested and found operational.

- Documentation that the firm conducted safety training for plant personnel regarding the proper operation of the ammonia refrigeration system.

- Certification that the system has been pressure tested in accordance with Section 538 of ASME B31.5-2013.

- Certification that visual inspection has been performed by a trained start-up technician on all piping, electrical wiring, supports, covers, and guards to insure the system is in proper order before start-up.

- Initial start-up procedure describing the steps the contractor will follow when performing system start-up.

- Log of activities and data taken during start-up to ensure that a benchmark for operation is available for future reference.

Leave a Reply